FRAISA – Maximum economy for autonomous work processes

Making economic efficiency fit for the future - to achieve this goal, FRAISA’s own production lines have been relying on autonomous processes for years. This benefits our customers, because it also allows us to support the efficient implementation of autonomous workflows in their production lines.

Machining without human process monitoring

In autonomous production lines, machines automatically adjust themselves for new processes, different products, or the manufacturing of product variants. Here too, our actions are based on our motto “passion for precision”, because as a technology partner we offer our customers products for maximum precision.

Optimal quality for maximum customer benefit

By consistently focusing on the development of future-oriented, state-of-the-art technology, we are steadily expanding our position in the global market. With seven sites worldwide and more than 500 employees, FRAISA is one of the leading manufacturers in the machining industry.

What matters to us is the actual benefit our customers derive from using FRAISA products. With our in-depth expertise in autonomous manufacturing, we offer extra added value and help increase the efficiency of our customers’ production lines.

Click on the individual headlines to find out more:

FRAISA Tool design

Lower production and logistics costs thanks to multi-functionality

FRAISA tools are known for high cutting performance. At the same time, FRAISA also offers MFC (multi-functional cutting) technology, which enables the tools to be used reliably in a wide range of materials.

Your advantage:

With MFC, you benefit from lower tool diversity, fewer

occupied magazine spaces in the machine, simpler logistics

and lower costs.

FRAISA Product quality

Consistent quality for top performance

Autonomous processes run in shifts with little or no personnel. It is crucial that the tools used work absolutely reliably and always deliver the same performance. With highly advanced autonomous processes, FRAISA achieves the highest consistency in product manufacturing.

Your advantage:

Due to the consistent quality of FRAISA tools, you can

rely on consistently high efficiency and performance.

FRAISA Cutting data

Greater efficiency in production

FRAISA invests around 50% of the total development budget in developing tested and analyzed real-world cutting data. The result is “Plug & Play” solutions, which remove the need for costly experiments in live operation.

Your advantage:

The high-quality cutting data from FRAISA

ToolExpert® guarantee fast and reliable implementation of

your autonomous processes.

FRAISA CAM integration

Efficient data import via online interfaces

The manual integration of tool and application data is often prone to errors and is time-consuming. FRAISA works with the most important manufacturers of leading CAM systems to develop and update fully automated online interfaces for our FRAISA ToolExpert®. These facilitate the automatic and error-free import of all tool-related data into one’s own CAM system.

Your advantage:

Importing cutting data directly into your own CAM

system reduces time requirements and error-proneness,

while increasing efficiency.

FRAISA Application consulting

Many years of expertise and intensive training courses

Process understanding is the key to success: In addition to their many years of professional experience, our FRAISA application engineers receive intensive training several times a year to ensure that they are always up to date with the latest technology. They sell solutions that take our customers’ production to a higher level of profitability.

Your advantage:

Your personal contact knows your individual requirements

and uses their expertise to find the best possible

solution for your needs.

FRAISA ReTool®

Reliability you can build on

Carbide tools are made from valuable raw materials, especially tungsten and cobalt - so reconditioning is usually worthwhile. FRAISA has a highly automated service center for industrial tool reconditioning, restoring original performance.

Your advantage:

Your reconditioned FRAISA tools can also reliably be

reused in autonomously operating processes.

Technological transformation:

Autonomy as a huge opportunity

This everyday phenomenon has been around a long time: automatic processes of the kind seen for example in machining centers. In autonomous work processes, machines automatically adjust themselves for new processes, different products, or the manufacturing of product variants.

Autonomous processes have the advantage of achieving high levels of machine utilization while simultaneously improving working conditions for employees. Late night and weekend shifts can be avoided if the machines are equipped for these periods during the day shift. FRAISA implemented these processes in its own production facilities years ago.

Key function of the tool manufacturer:

“Tool-component” interaction as a core competency

In autonomous manufacturing, the contact zone between component and tool represents a highly complex area. Extreme pressures, friction, fluctuating temperatures and chemical processes occur here. These effects ultimately determine the quality of the component, the production costs, and the economic efficiency of the process.

As a tool manufacturer, FRAISA engages intensively with the contact zone processes. The key to good-quality and sustainable tool development is a fundamental understanding of these variables and their interactions.

Digital Twins from FRAISA:

For virtual representation of the production processes

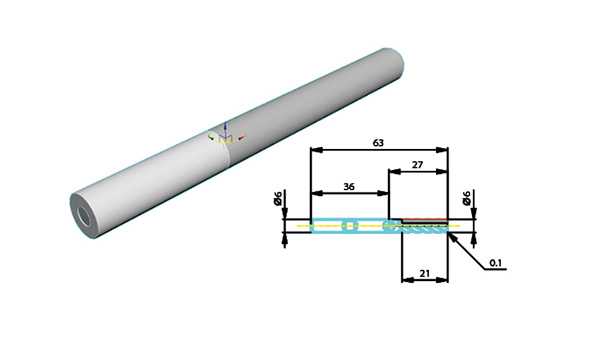

Exact geometric data (DIN/ISO-compliant) are available in various formats. They are kept up-to-date and can be downloaded easily and securely from FRAISA ToolExpert®.