Watch industry

The fabrication of high-quality watches requires precision work and flawless surface qualities. With its MicroX technology, FRAISA offers a perfect solution for high-precision micro-milling in finishing and superfinishing. It should therefore come as no surprise that the first product made by FRAISA’s founder Johann Stüdeli back at the beginning of the company’s history in 1934 were milling tools for the watch industry.

Products

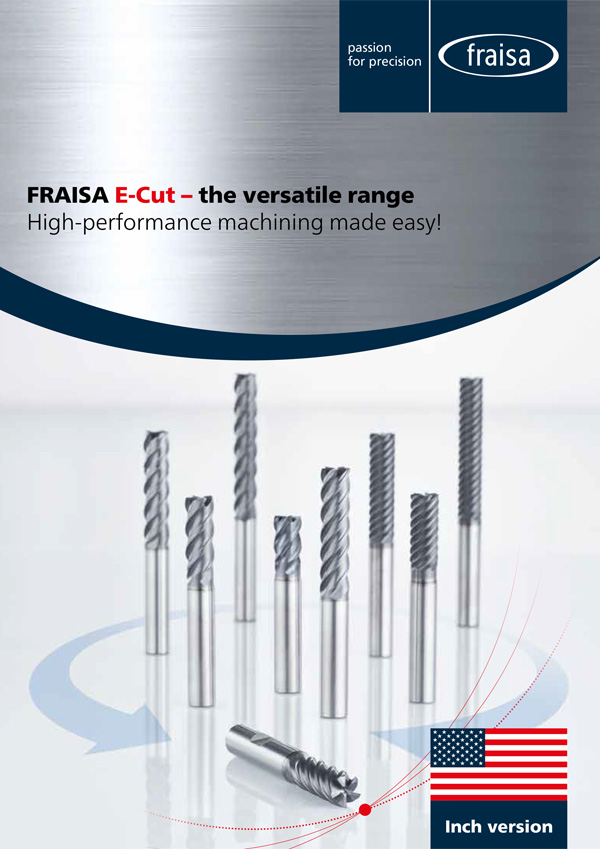

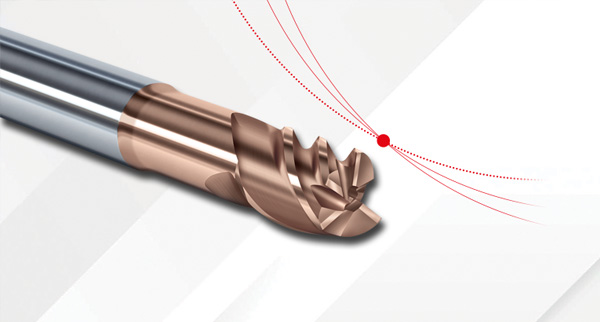

E-Cut

The new additions to the E-Cut milling program from FRAISA - especially the short versions – impress with their incredible performance.

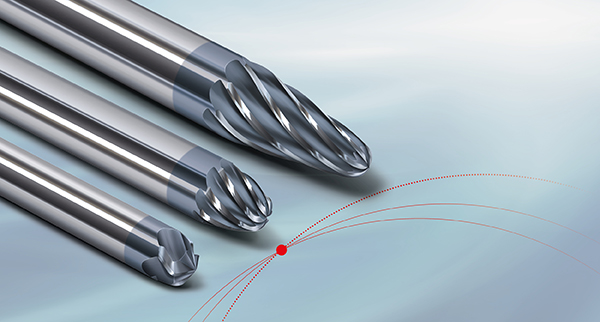

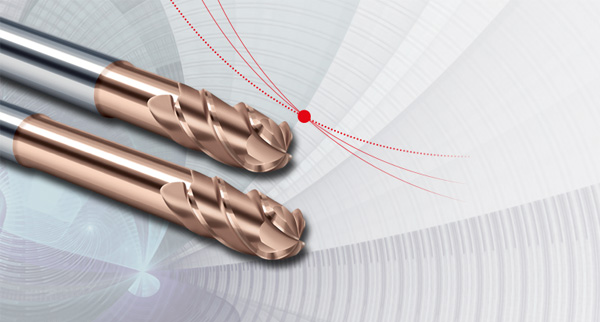

Favora® tool concept

Favora® tools from FRAISA are characterised by their great universality, high performance and long service life - making them unbeatably efficient.

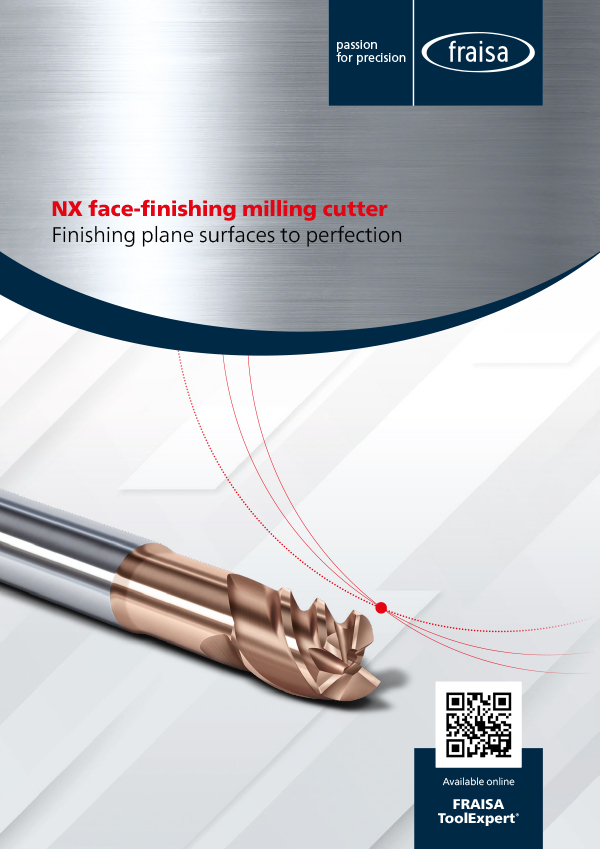

NX face-finishing milling cutter

Discover the latest innovation from FRAISA - the NX end finishing cutter machines flat surfaces visually and measurably in outstanding top quality.

SpheroX

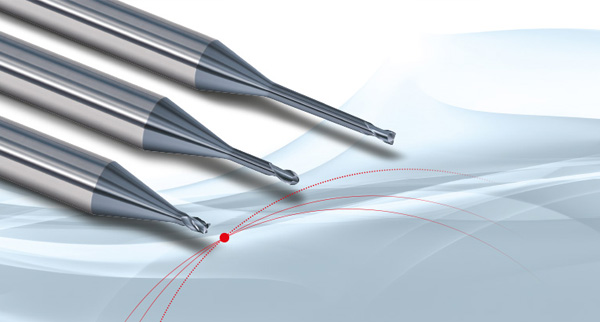

Impressive perspectives with the new generation of SpheroX milling cutters. Overcome the limits of classic HSC machining with HDC processes.

FRAISA E-Cut

The FRAISA E-Cut milling concept combines a very wide range of applications with precisely calculated and verified application data.

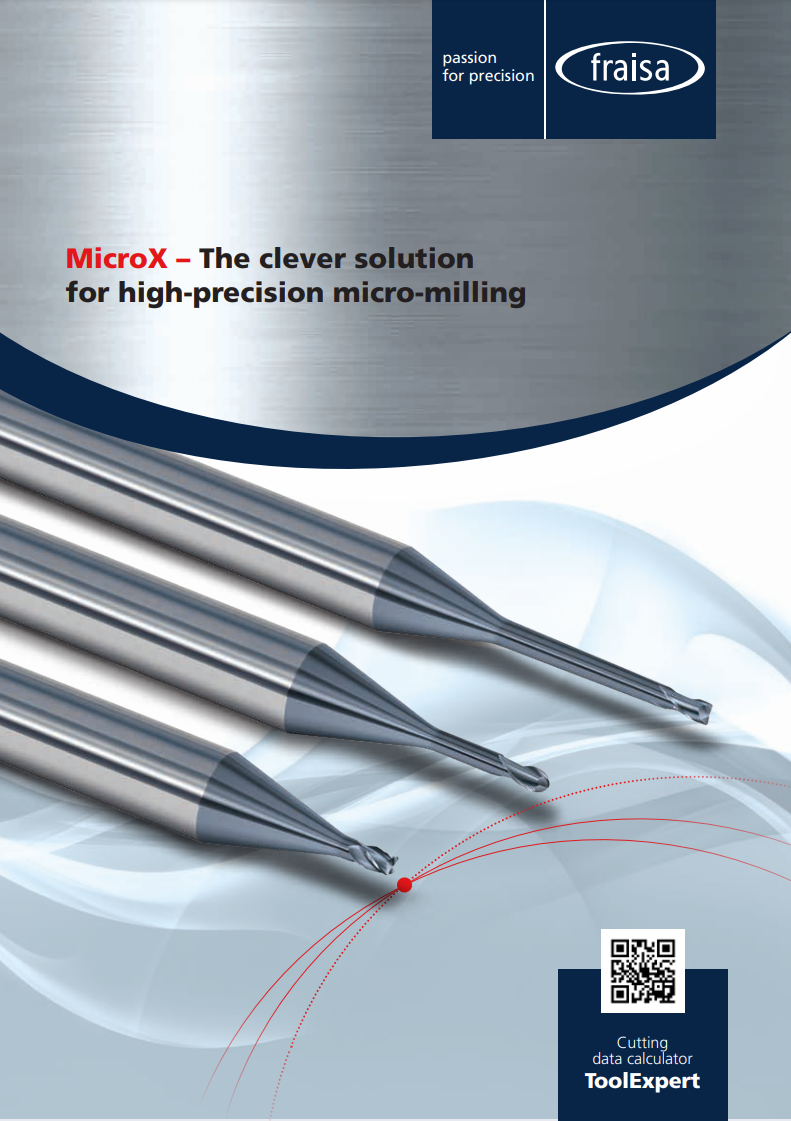

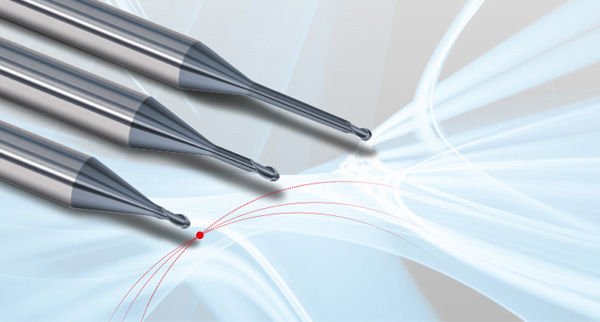

Micro-milling of super-hard molds

Discover the efficiency of FRAISA MicroHX ball nose end mills - economical, precise machining of very hard materials with hardness > 60 HRC.

Services

FRAISA ReTool®Services

Living the circular economy for precision tools – made by FRAISA: The three sustainable offers of the FRAISA ReTool®Services extend the tool life cycle…

FRAISA ToolCare®

With the new tool management system ToolCare® the tools utilized in the production facility can be stored in a clearly organized manner and efficiently…