Milling Monoblock

Milling is an important manufacturing solution in the metalworking sector. Precision, high-quality milling tools are required to produce flat surfaces or sophisticated three-dimensional contours. FRAISA’s product range includes milling cutters for a wide variety of materials, especially for 3D machining and tools with special shapes. Additional services round off the offering: Cutting data calculators available online optimize the use of tools and therefore productivity.

Filters

Milling in steel, stainless steel, titanium and nickel

- Roughing

- Finishing

- Face-finishing

- Penetration with helical interpolation and ramping

- Micromachining

Multifunctional milling with up to 96 or 132 applications

Milling in 3D machining for mold making and complex components in soft to high-hard materials

- Ball nose end milling

- Circular segment milling

- Corner radius milling

- High feed cutting HFC

- 3D micromachining, ball nose end and corner radius

Milling in aluminum and copper

- Roughing

- Finishing

- Face-finishing

Milling in graphite

Milling with special shapes

Products

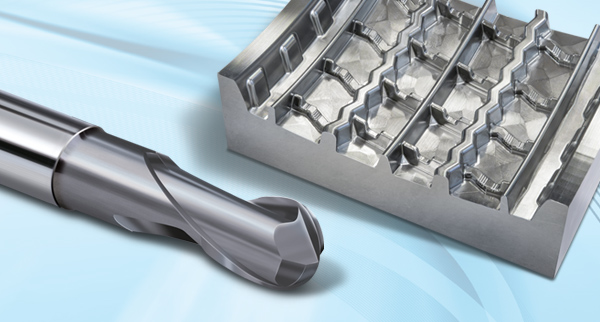

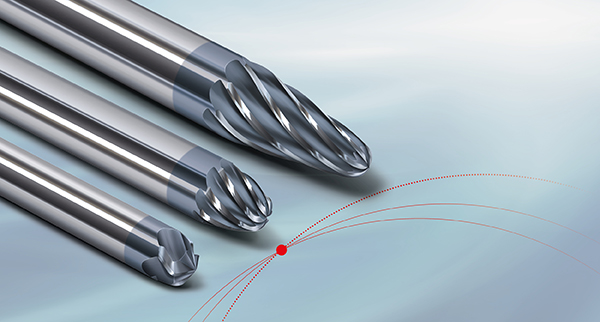

Sphericut MULTICHROM

Optimally equipped for specific challenges in 3D machining, the new Sphericut precision ball is an innovative milling tool developed by FRAISA specifically…

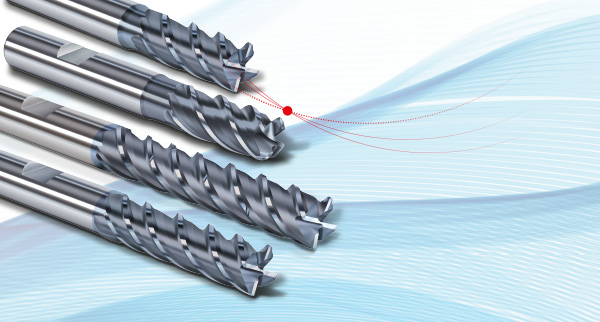

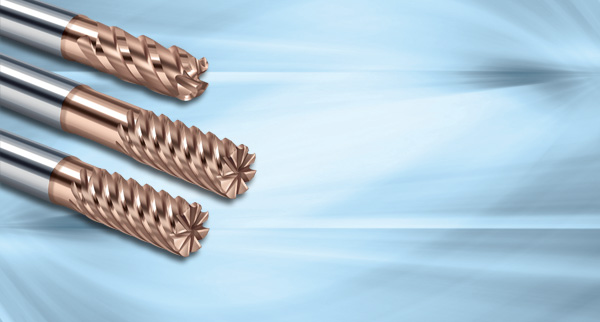

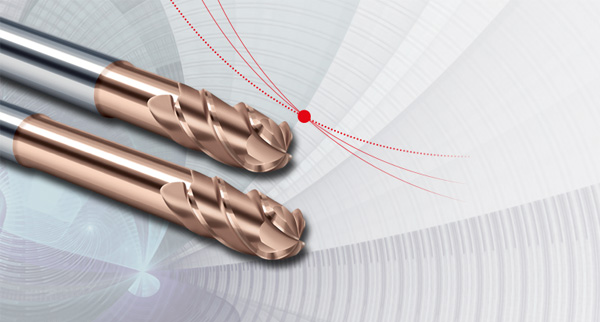

FRAISA SteelCut

FRAISA has developed the new SteelCut milling system with a very broad material coverage and robust behavioral characteristics in order to be able to machine…

E-Cut

The new additions to the E-Cut milling program from FRAISA - especially the short versions – impress with their incredible performance.

MFC Alu

The completely newly developed MFC Alu milling system is the first to present four-edged high-performance milling cutters for machining aluminium, copper,…

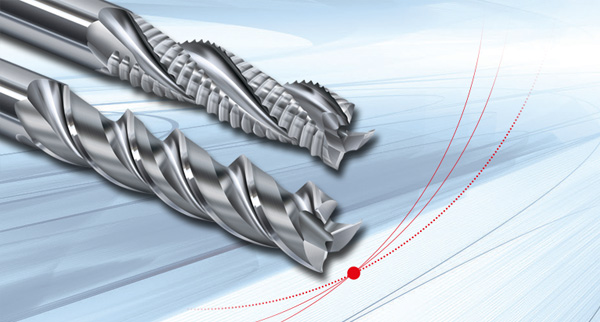

Aluminum roughing

With the new profiled roughing tool, FRAISA presents an extremely economical and productive solution for aluminium machining.

Favora® tool concept

Favora® tools from FRAISA are characterised by their great universality, high performance and long service life - making them unbeatably efficient.

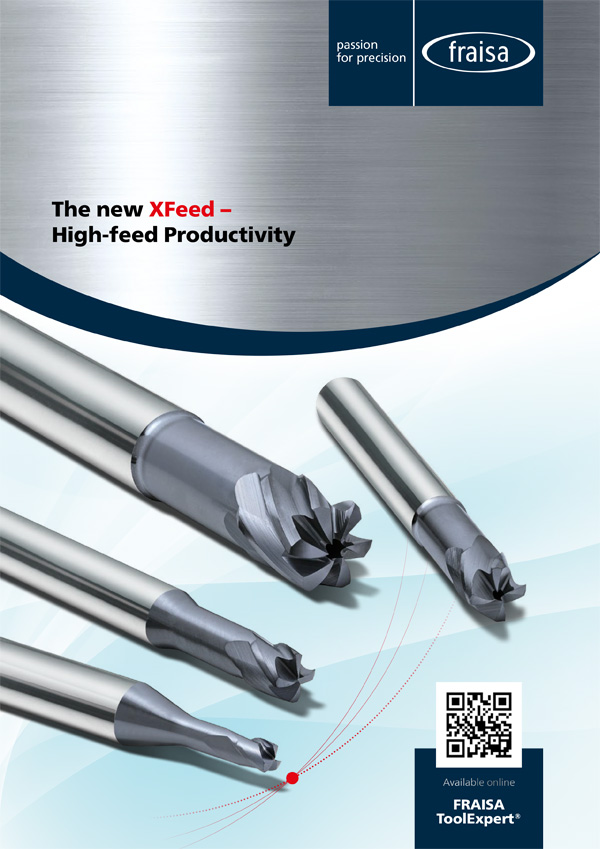

XFeed – High-feed Productivity

With its new XFeed milling cutter, FRAISA has found the perfect solution for high-feed machining of medium- to high-strength steels.

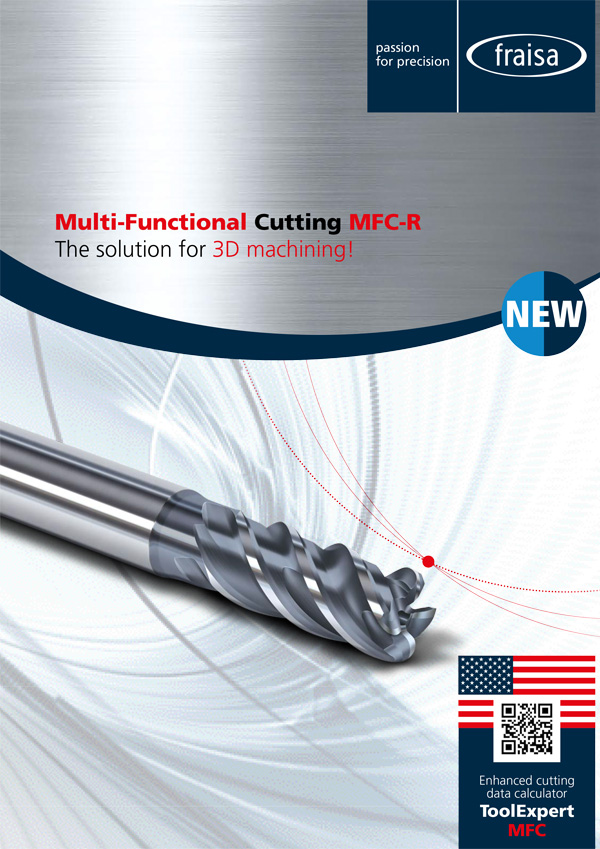

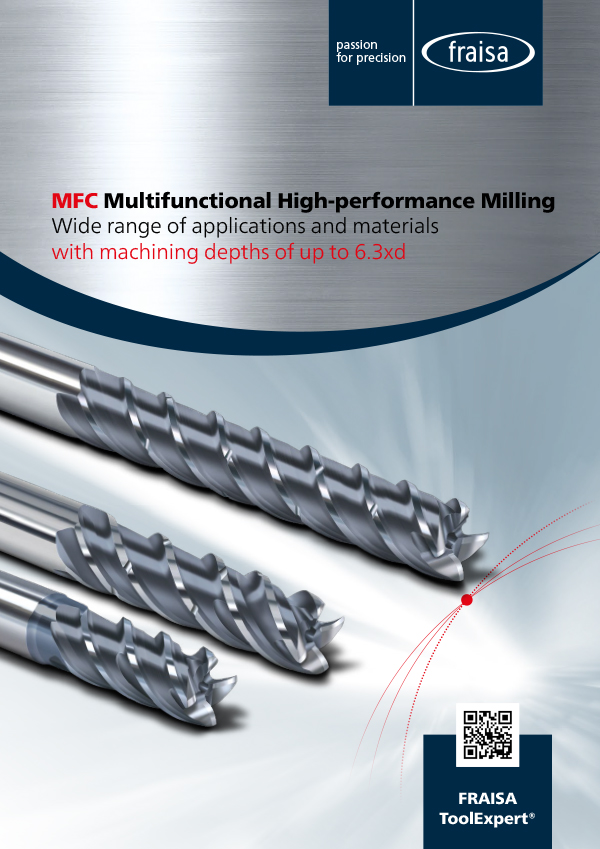

MFC

Multifunctional MFC tools from FRAISA for up to 154 areas of application. Reduce inventory and set-up costs as well as tool change times.

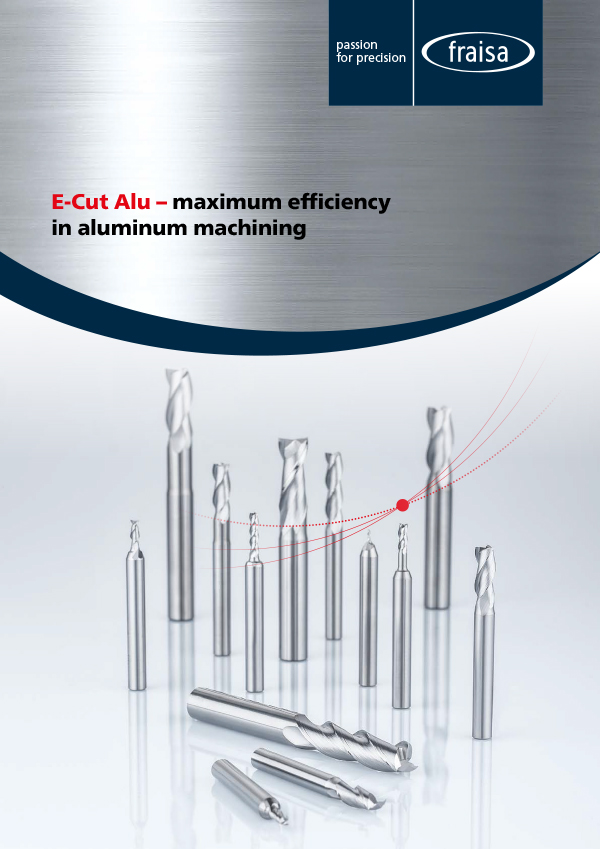

E-Cut Alu

FRAISA presents the E-Cut Alu family for machining aluminum: The totally new, smooth-edged, high-performance milling system includes over 272 articles…

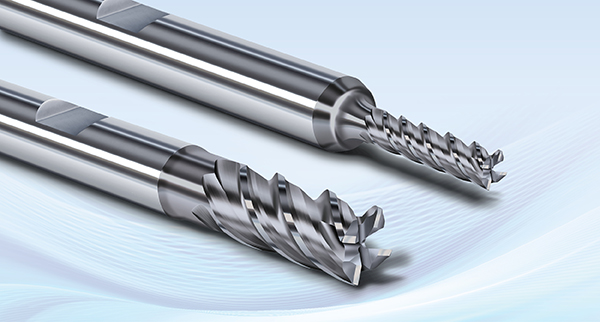

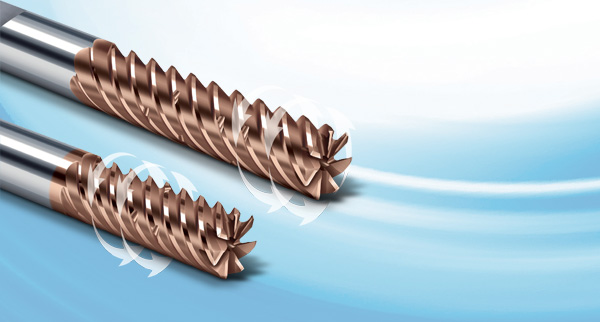

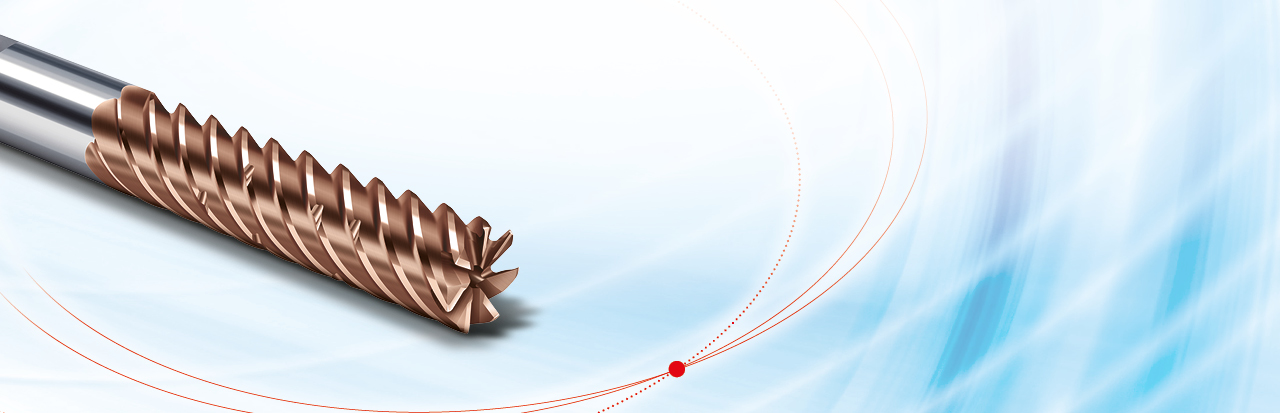

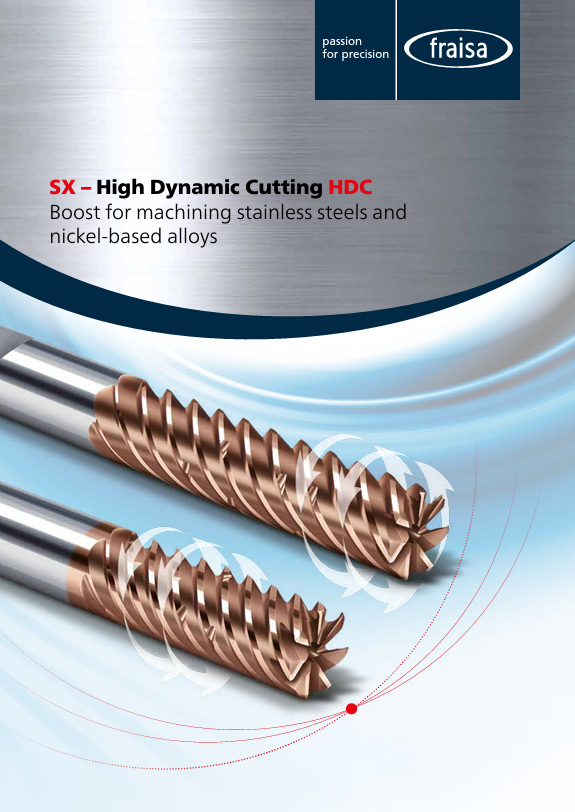

SX – High Dynamic Cutting HDC

Multi-flute SX high-performance milling cutters for machining stainless steels and difficult-to-cut materials. Especially for HDC machining.

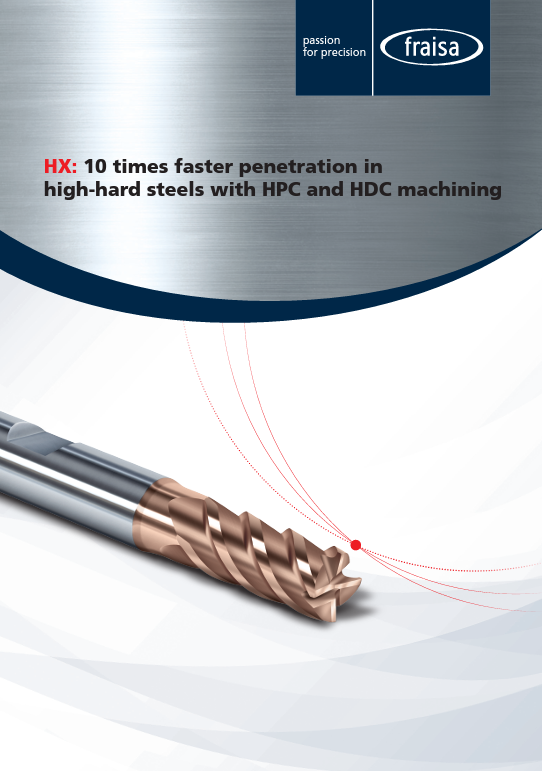

HX and XSpeed-H

The HX and XSpeed-H are perfect additions to the HX family, which has been specifically designed for high-performance milling of high-hard steels.

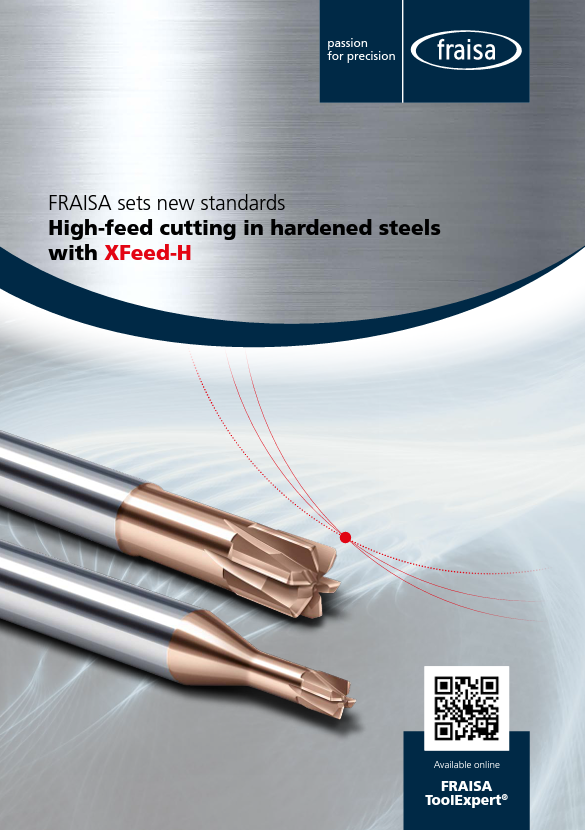

XFeed-H

With the new XFeed-H milling cutter, FRAISA has produced the perfect tool for realizing HFC processes in hardened steels.

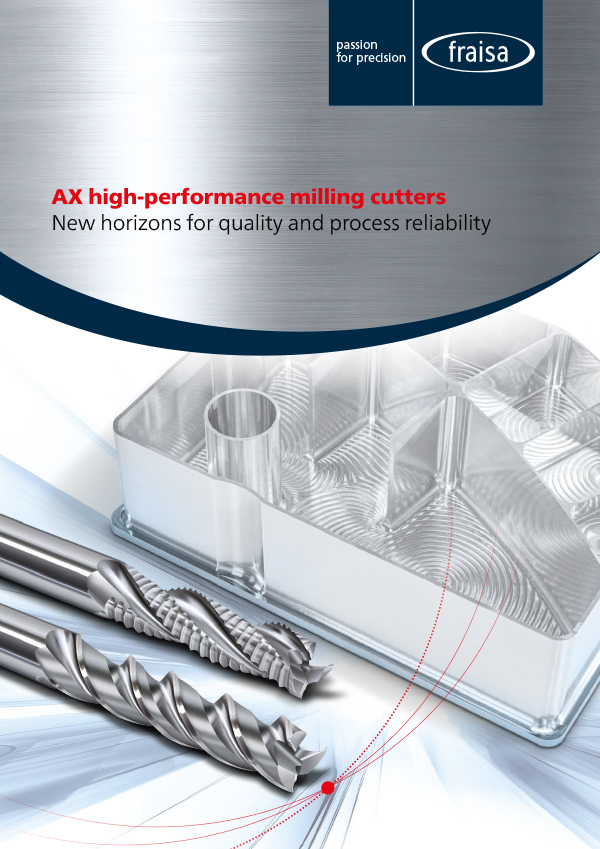

AX high-performance milling cutters

In the field of roughing technology, the AX-FPS has set new standards in terms of maximum performance and low power consumption.

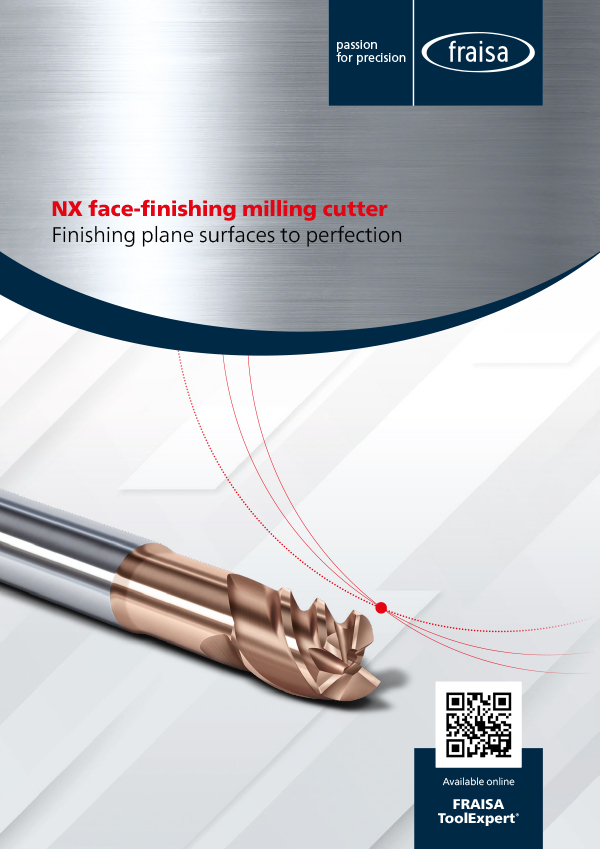

NX face-finishing milling cutter

Discover the latest innovation from FRAISA - the NX end finishing cutter machines flat surfaces visually and measurably in outstanding top quality.

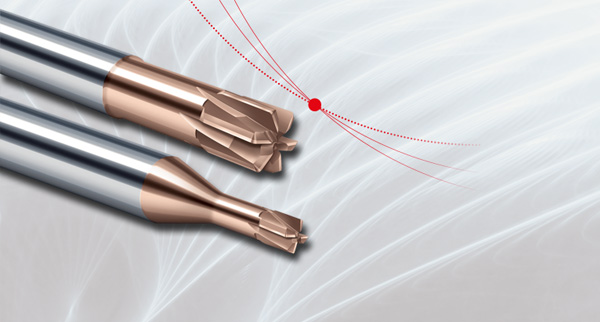

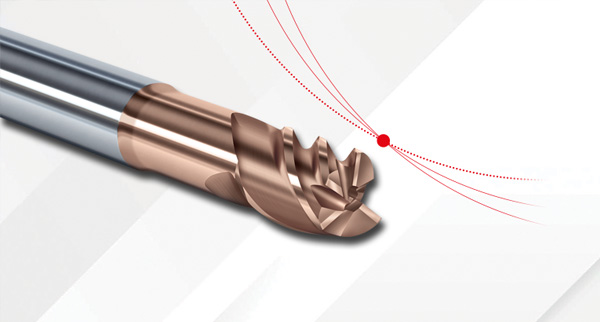

SpheroX

Impressive perspectives with the new generation of SpheroX milling cutters. Overcome the limits of classic HSC machining with HDC processes.

FRAISA E-Cut

The FRAISA E-Cut milling concept combines a very wide range of applications with precisely calculated and verified application data.

AX-FPS

AX-FPS - Productivity gains thanks to perfect coordination of the tool and machine environment

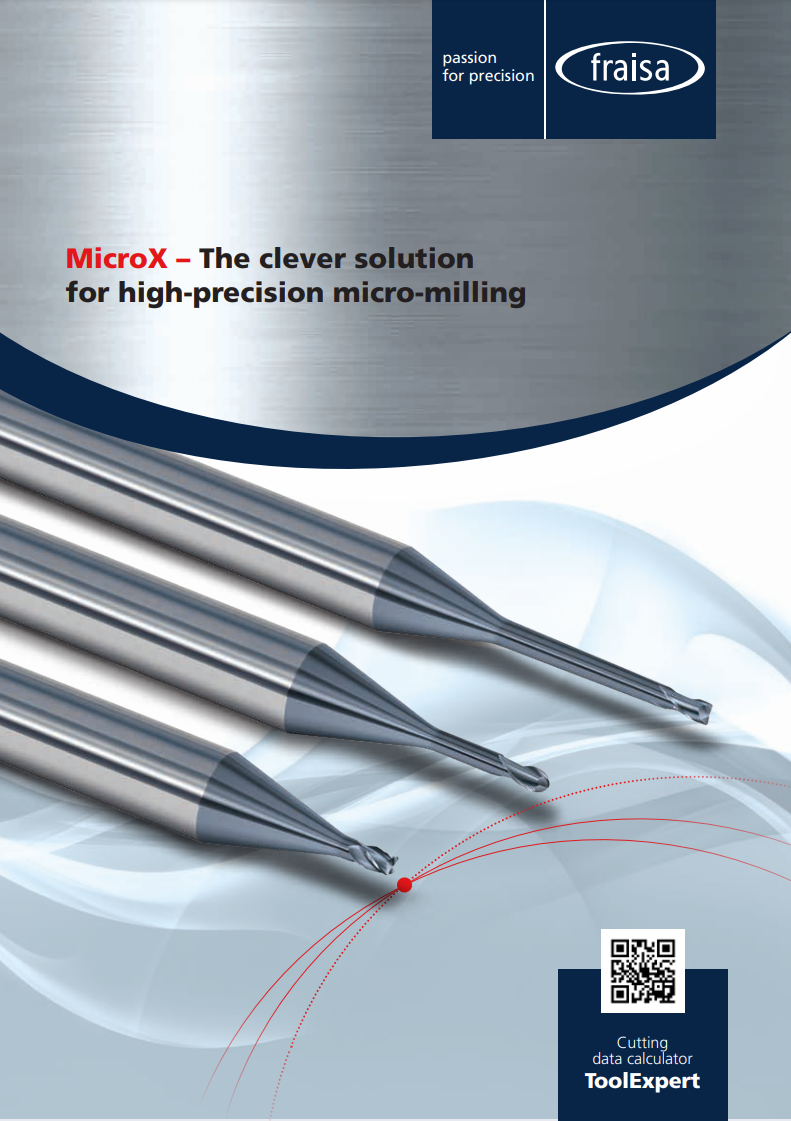

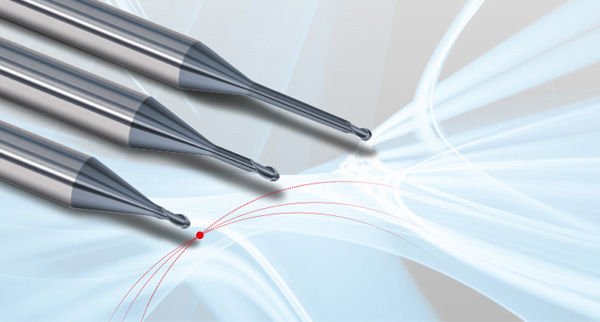

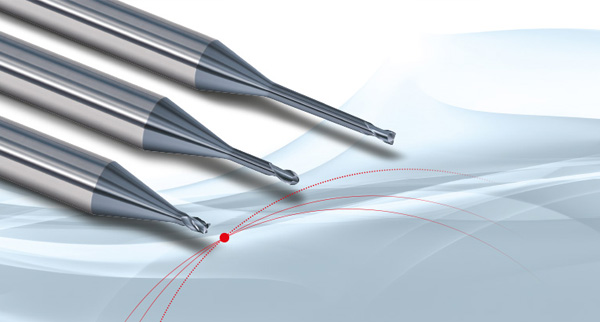

Micro-milling of super-hard molds

Discover the efficiency of FRAISA MicroHX ball nose end mills - economical, precise machining of very hard materials with hardness > 60 HRC.

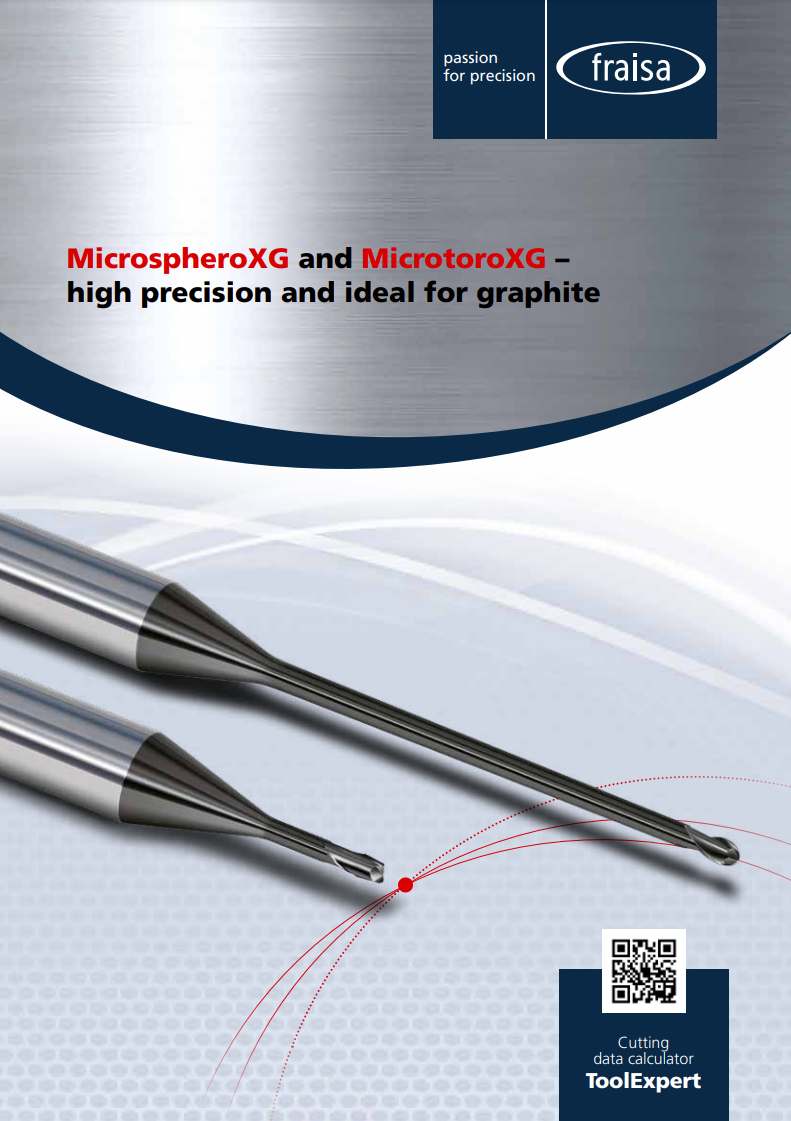

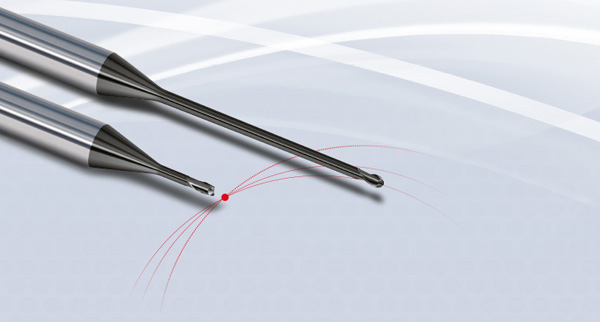

Micro-milling of graphite

The clever solution for high-precision milling of graphite materials now comprises 219 items with diameters ranging from 0.1 to 6.0 mm.

Downloads

![[Upgrade] High-performance milling of aluminium AX-FPS](/assets/img/branchen/prospekte/AxFpsThumbDownloads_EN.PNG)