Interface FRAISA ToolExpert®

High-quality cutting data determines the efficiency and safety of machining processes. FRAISA has made another step toward process optimization by directly integrating data using online interfaces: Through the integration of an XML or JSON interface, a direct import of cutting data into the CAM or TDM system is now possible. Time requirements and the susceptibility to error are significantly reduced compared to manual data entry.

Precise cutting data is transferred directly between FRAISA ToolExpert® and TopSolid via a bidirectional XML interface. The direct online data exchange significantly reduces the time required and the susceptibility to errors compared to manual input.

More information

By integrating an XML interface, the process-reliable geometry and cutting data determined in FRAISA ToolExpert® can be imported directly and quickly into the hyperMILL® CAM software.

More information

Automated data integration between FRAISA ToolExpert® and mdm to optimize production processes: Two different workflows are available to choose from to import the checked geometry and cutting data quickly and easily via a JSON interface. Additional use cases can be added at any time for more extensive processing.

More information

An interface is currently available to CAM users for the direct transfer of geometry and cutting data between FRAISA ToolExpert® and NX Tools.

Update!

The use of exact cutting data has a direct influence on the safety of the machining processes and the efficiency of the production. Particularly in times of technological change, and the increase in automation, it is our goal to support our customers with these challenges in the best way possible.

FRAISA invests around 50% of the total development budget into gathering tool- and material-specific cutting data. More than two million of these data items are available in our online cutting data calculator, FRAISA ToolExpert®, and are the basis for optimal usage of FRAISA tools.

FRAISA’s sustainability concept is also reinforced by using precise cutting data: Tools used correctly have a longer service life. In addition to that, the cutting data can be applied even after reconditioning with FRAISA ReTool®.

Direct data integration via online interfaces

Manually entering application cutting data into CAM or TDM systems is often error-prone and time-consuming. With direct integration of data through online interfaces, FRAISA has once again taken a successful and revolutionary step towards process optimization. Through the integration of an XML or JSON interface, a direct import of cutting data is now possible. Time requirements, and the susceptibility to error, are reduced and the efficiency is increased - an added value for our customers.

The FRAISA ToolExpert® and interface technologies will continually be developed in the future so that our customers are supported with the selection of tools, the most effective strategies and the most suitable cutting parameters.

To the FRAISA ToolExpert®For greater efficiency in your production

Precise: Identification of perfectly coordinated, tool and material-specific cutting data

Precise: Identification of perfectly coordinated, tool and material-specific cutting data

Simple: Mobile data access at any time and from anywhere without software downloads

Simple: Mobile data access at any time and from anywhere without software downloads

Fast: Finding application parameters with just a few clicks without having to register

Fast: Finding application parameters with just a few clicks without having to register

Flexible: Searching for tools and materials to be machined as required

Flexible: Searching for tools and materials to be machined as required

Comprehensive: Calling up cutting data from a database of more than 11,000 materials

Comprehensive: Calling up cutting data from a database of more than 11,000 materials

User-friendly: Intuitive operation thanks to the new, responsive design

User-friendly: Intuitive operation thanks to the new, responsive design

Functional: Ordering of the selected tool via link directly in the E-Shop

Functional: Ordering of the selected tool via link directly in the E-Shop

Secure: Direct import of cutting data through the integration of an XML or JSON interface

Secure: Direct import of cutting data through the integration of an XML or JSON interface

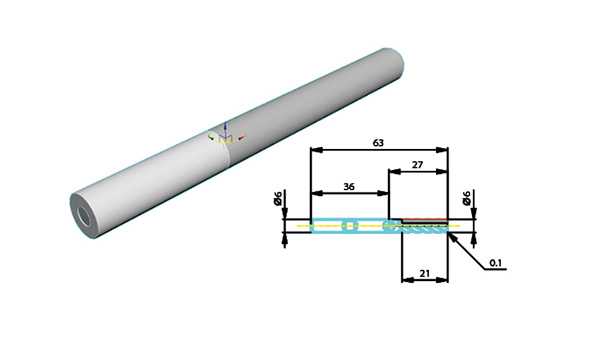

Vivid: Digital Twins - easy download of exact geometry data (DIN/ISO-compliant)

Vivid: Digital Twins - easy download of exact geometry data (DIN/ISO-compliant)

Digital Twins from FRAISA:

For a virtual representation of production processes

Precise geometry data (DIN/ISO-compliant) is available in a wide variety of formats. They are constantly kept up to date and can be downloaded easily and securely from FRAISA ToolExpert®.