At FRAISA we do everything to ensure our customers succeed.

In a highly competitive market, it is a matter of being quicker, better and cost-effective.

This is because our customers‘ success is also our own success.

An uncompromising demand for quality and absolute customer focus are the prerequisites for this.

Therefore, we do not consider ourselves to be a supplier; we see ourselves as a partner that our customers can rely upon for all requirements. Hence our motto is »optimum quality and comprehensive service for maximum customer benefits«.

For this purpose, our emphasis is placed upon a continual innovation process that guarantees future-oriented cutting edge technology through research and development.

Only in this way is it possible for our products and services to always satisfy the current market requirements. And only in this way is it possible for our customers to obtain the added value that they quite rightly expect from our products and services.

As an independent family company, we attach great importance to this special »Spirit of FRAISA«. It is supported and brought to life by our highly-qualified technicians, engineers and consultants. As a technology company, we offer products with high precision. However, we also attach importance to the »human factor«. Or rather: to the creativity of our employees and the trust of our customers.

Honorary Chairman of the Board of Directors

Josef Maushart

The Swiss family company with international orientation

FRAISA produces cutting tools for metal cutting processes throughout the global market. Founded in 1934, the company currently employs more than 500 people and is one of the leading manufacturers in this industry.

Long-standing commitment and sustainable development are values that shape FRAISA‘s corporate philosophy. This philosophy assumes continuous investments in company, product and personnel development as well as the will to achieve a long-term and partnership-based customer relationship, complete with individual support, personal consulting and intensive on-site contact in equal measure.

FRAISA represents high-technological demand, creative engineering, quality and teamwork at all levels. Our objective is to minimise the production costs for our customers and to maximise productivity in their plants with our high-performance tools and services. At the end of the day, the actual benefit to our customers is what counts for us.

Positive response

FRAISA partners not only appreciate our process expertise and market proximity; they also use these characteristics in a profitable manner. Independent customer satisfaction surveys confirm this.

At FRAISA, the know-how of our development engineers, the knowledge of our application consultants and the experiences of our customers blend into a continuous process of innovation. The result: progress achieved by technologically pioneering and future-proof product solutions.

In order to actively mould the technological change, we make targeted investments in research and development, in the latest machines and equipment, and particularly in highly-qualified technicians and engineers.

Over the years, we have established a tight network of international specialists in the fields of machinery, material and surface technology, in which research and development is performed. This is the foundation for the superior FRAISA technology and for the performance of our products, reaching over 12,000 in number.

Research and development combined with precision and passion only works effectively in a team with a system.

High-performance products for every requirement

The extensive product range from FRAISA consists of over 12,000 standard and special products. During the annual revision of the catalog, new products are regularly added, and each one is carefully developed and validated.

When selecting the right tool for the application, the most technologically advanced tool is not always the most economical. This is why FRAISA milling tools are divided into four classes:

- The “X-Generation” products demonstrate their superior performance even in the most challenging applications.

- The “Performance” class offers products with excellent operation in a broad range of applications.

- The “Favora®” class includes powerful and competitive products.

- The products in the “HSS” performance class are effective for small jobs.

Our uncompromising quality standard is reflected in all tool classes and follows our FRAISA “passion for precision” philosophy.

Production and quality assurance

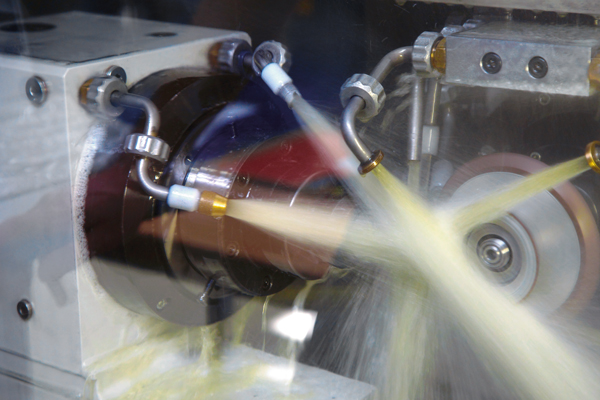

FRAISA works with the most up-to-date production machines from selected partners. The technological standard is constantly upgraded in close cooperation. From soft machining and cylindrical grinding, the actual tool grinding to surface technology, all production processes take place in our own facilities.

We attach just as much importance to the innovative further development of our production processes as to the actual product development. Our measurement technology includes all areas of geometry and materials testing, in keeping with current technological know-how.

Test and application Centers

CAD/CAM simulations, Finite Element Methods (FEM) and scientific findings have changed the developmental processes of tools in recent years. Yet, new products undergo numerous technical tests before they enter serial production.

And the actual product development at FRAISA is followed by application development. Here, optimal application strategies and application data for our new products are worked on in a state-of-the-art application environment.

Only when a perfect and validated product is available and the application strategies have been determined, do we bring our products onto the market. This handover takes place in connection with comprehensive training sessions for employees, sales partners and customers. As even top products will actually only become fully productive when the required knowledge base is available for optimal application.

Customer service

One of our exceptional characteristics is the balanced combination of innovative products, comprehensive knowledge transfer and an exemplary range of services. What once started off as the first cutting data book for milling tools, is today a comprehensive information system in printed and electronic form.

More than 100 experienced consultants are available to our customers by phone and on site. They all have one goal, namely to provide the best possible advice for our customers. Our technology teams in Germany, Switzerland, Hungary and the USA annually design 3,000 special customised solutions.

Every month, around 1,000 customers use our service for the ecologically valuable, true-to-original reconditioning of tools. And over 800 customers bank on our ToolCare® premium package, which through cross-company cooperation offers true added value to both partners.

Service tools

For increasing productivity and profitabil ity, high-performance tools from FRAISA are always the right choice. The addition al offer of perfectly coordinated services significantly reinforces the advantages of our tools even further. By reducing effort and resource consumption, the benefits for our customers are maximized. For that reason our focus is on continually devel oping our comprehensive range of ser vices — and naturally by increasingly using digital media.

FRAISA ToolCare®

A lot of overview for more efficiency: The ToolCare® elec tronic tool management system guarantees a significant pro ductivity increase. Supported by cloud-based software, all tools used for production can be stored and found easily. More than 700 FRAISA customers are benefiting from this efficient tool management system with ToolCare®. Continuous develop ment of the software ensures sustainable use of ToolCare® for customers.

More information

FRAISA ReTool®Services

With the cost- and resource-friendly FRAISA ReTool®Services, FRAISA is living the circular economy for precision tools. The industrial tool reconditioning service FRAISA ReTool® guar antees that tools are restored to their original tool perfor mance with the FRAISA performance guarantee. If tools can no longer be reconditioned, we feed them into the recycling process using FRAISA ReTool®Blue and thus close the raw material cycle. The new service offer FRAISA ReTool®Green allows the reconditioning of used FRAISA tools from custom ers who cannot or do not wish to use FRAISA ReTool® for any reason – FRAISA then sells the reconditioned tools to custom ers that need them.

The FRAISA ReTool®Green service is not yet available in all markets. Your FRAISA contact person will be happy to assist you with any queries you may have.

More information

FRAISA ConcepTool

At the Sárospatak production site in Hungary, FRAISA man ufactures customized tools fitting customer-specific require ments. These customized tools enable the customer to imple ment desired processes and increase productivity. Of course, the production of customer-specific solutions is carried out using state-of-the-art technologies and high-quality machines and materials.

More information

FRAISA ToolSchool and FRAISA ToolExpert®

For the profitable use of our high-performance tools, the right machining strategy combined with optimal cutting data is elementary. With our FRAISA ToolExpert® online cutting data calculator, we ensure the transfer of this valu able knowledge to our customers. In addition, with FRAISA ToolSchool we offer application seminars on the latest inno vations in chipping technology. Our time- and cost-saving digital customer seminars live from the FRAISA ToolSchool have been continuously expanded. We invested in new vid eo technology for this purpose, giving customers the feeling that they are attending the tool demos live in Bellach.

More informationCustomer-oriented system solutions

SERVICE

- FRAISA ToolCare®

- FRAISA ReTool®Services

- FRAISA ConcepTool

- FRAISA ToolSchool

- FRAISA ToolExpert®

PRODUCT GROUPS

- Monoblock milling tools

- Carbide and HSS

- Indexable insert milling tools

- Modular milling system

- Taps and thread formers

- Carbide drills

- Thread milling tools

PERFORMANCE CLASSES

- X-Generation:

Superior performance in challenging applications - Performance:

Excellent performance and broad application range - Favora®:

Powerful and competitive - HSS:

Allrounder for small jobs

PROCESSES

- Innovation

- Production

- Quality management

- Client Research

- Customer service

Network

With seven branches worldwide, FRAISA is represented in all relevant markets around the globe. Each individual company has very specific capabilities making it individ ually successful.

FRAISA SA in Switzerland stands for innovative product and technology development as well as highly automated production. In addition, the FRAISA ToolSchool in Bellach is the hub for highly specialized know-how transfer.

FRAISA GmbH in Germany is a recognized expert for FRAISA ReTool/reg; industrial tool reconditioning, one of the three cost-saving and resource-friendly FRAISA ReTool®- Services. The team also takes care of FRAISA ReTool® or ders from other FRAISA companies.

FRAISA Hungary’s state-of-the-art plant in Sárospatak uses FRAISA ConcepTool to manufacture customized tools to meet customer-specific requirements and also produces our high-performance tools at particularly fa vorable conditions.

Our sales companies in China, Italy, France, and the US, as well as all our sales departments worldwide, serve as the group’s face for working with our customers. They listen to their needs and ensure that this valuable information gets put to use in our technology departments.

All companies stand jointly for the FRAISA Group of com panies and complement each other in their respective services. This way, we offer our customers worldwide the sum of all competencies and, through a maximized range of services, an additional real added value.

All our companies are certified according to ISO 9001, ISO 14001 and OHSAS 18001.