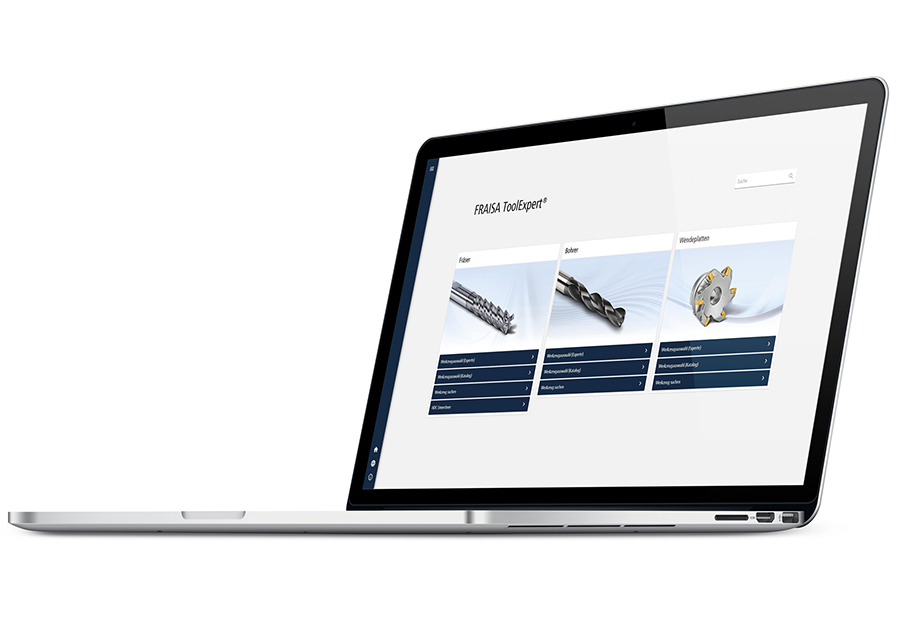

Personal application consultation and optimum cutting data in FRAISA ToolExpert®

Efficient and precise calculation of cutting data

Versatile application for various machining tasks

Simple operation and time saving

Selection from 11,000 materials

Data export and CAM interfaces

Maximum process reliability

Maximum process reliability thanks to optimum cutting data from the FRAISA ToolExpert®

To ensure a reliable and efficient milling process, we provide the optimum cutting data for each of our tools.

These parameters are precisely matched to the respective material and machining requirements to ensure maximum

tool life and process reliability.

In the FRAISA ToolExpert® cutting data calculator, the ideal speeds, feeds and infeeds for the respective

application can be determined quickly and precisely. This not only extends tool life, but also ensures

consistently high machining quality.

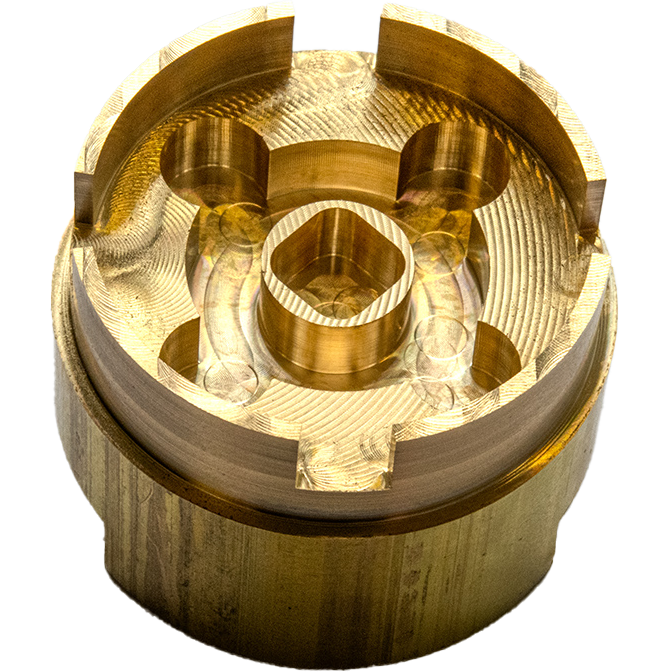

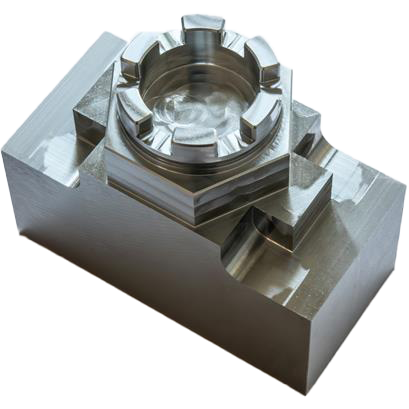

The following two components were milled using our new E-Cut tools. The cutting data for reliable tool use was

determined using our FRAISA ToolExpert cutting data calculator.

E-Cut, normal version

Component

- HPC roughing

- HDC-P roughing

- Helix plunging

- Pre-finishing

- Finishing

E-Cut, short version

Component

- Roughing HPC

- Helix plunging

- Roughing HPC Grooving

- Finishing

Our experienced technical application consultants support our customers at all times in the selection of the right tools and optimum process design. Whether it's about the right cutting strategy, fine-tuning the machining parameters or specific challenges in the milling application - the FRAISA team of experts provides targeted assistance so that the full potential of the tools can be exploited.

With the E-Cut milling program, you can rely on maximum efficiency, quality and dimensional accuracy - supported by optimum cutting data for maximum process reliability and expert application advice.

Our other E-Cut products

You might also be interested in

E-Cut - normal length design for minimal burr formation and first-class surface qualities

E-Cut - short length design for high tool stability thanks to short cutting edge