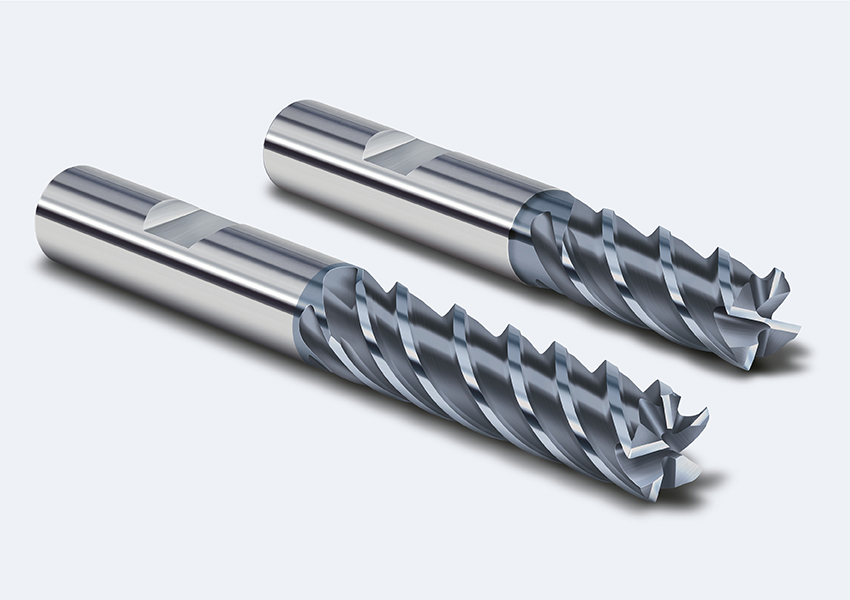

FRAISA E-Cut cylindrical milling cutters – highly efficient and extremely economical

Easy to use

Highly efficient

Extremely economical

Suitable for use in many materials

HPC and HDC processing

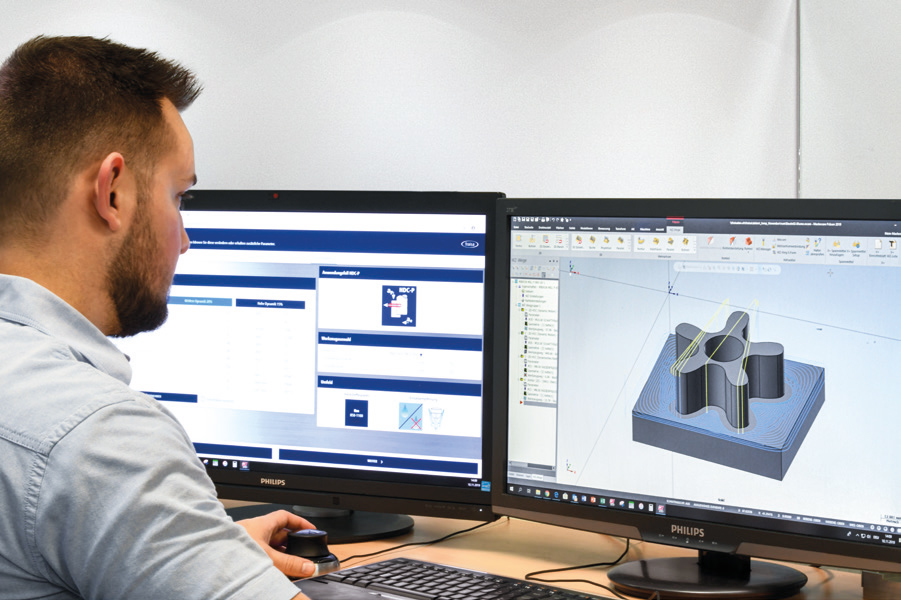

Reliable application data in FRAISA ToolExpert®

Cylindrical milling cutters from the FRAISA E-Cut series: versatility meets precision

The cylindrical milling cutters from the FRAISA E-Cut range feature innovative technologies that enable a wide variety of milling strategies for a multidue of materials, making them true all-rounders that are easy to use. Our E-Cut milling cutters achieve the best results in HPC and HDC machining and are extremely powerful, quiet, and easy to cut with.

Thanks to the intelligently designed range with a well-thought-out selection of lengths and tooth configurations, they are particularly versatile—from roughing to finishing and in a wide variety of materials such as steel, stainless steel, titanium, and cast materials.

In combination with our innovative service tools such as the FRAISA ToolExpert® online cutting data calculator, the FRAISA ToolCare® tool management system, and FRAISA ReTool® industrial tool reconditioning, these high-performance tools ensure efficient processes and sustainable performance.

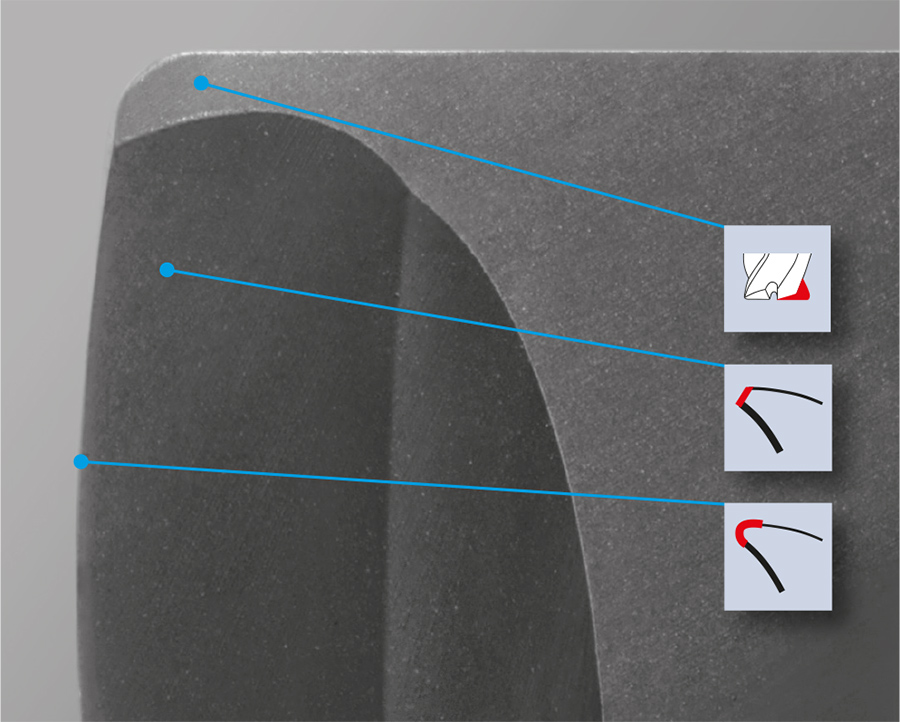

Innovative technologies for perfect results

As a special feature, FRAISA E-Cut tools have a protective chamfer with a chip former as well as a small corner radius. This reinforces the cutting edge and enhances performance. To improve performance, process reliability, and service life, the cutting edges of these high-performance milling cutters are conditioned.

The chip former at the main cutting edge is also noteworthy. This has been designed in such a way that the chips are formed perfectly and the length of time that the chip and the tool are in contact with each other is minimized. This results in smooth running characteristics and a long service life.

Our milling cutters at a glance:

Standard version

Medium length version

5.2xd version

FRAISA E-Cut – the compact range

FRAISA E-Cut finishing cutters – expanded range for perfect surface finishes