MicroHX – the best choice for super-hard steel

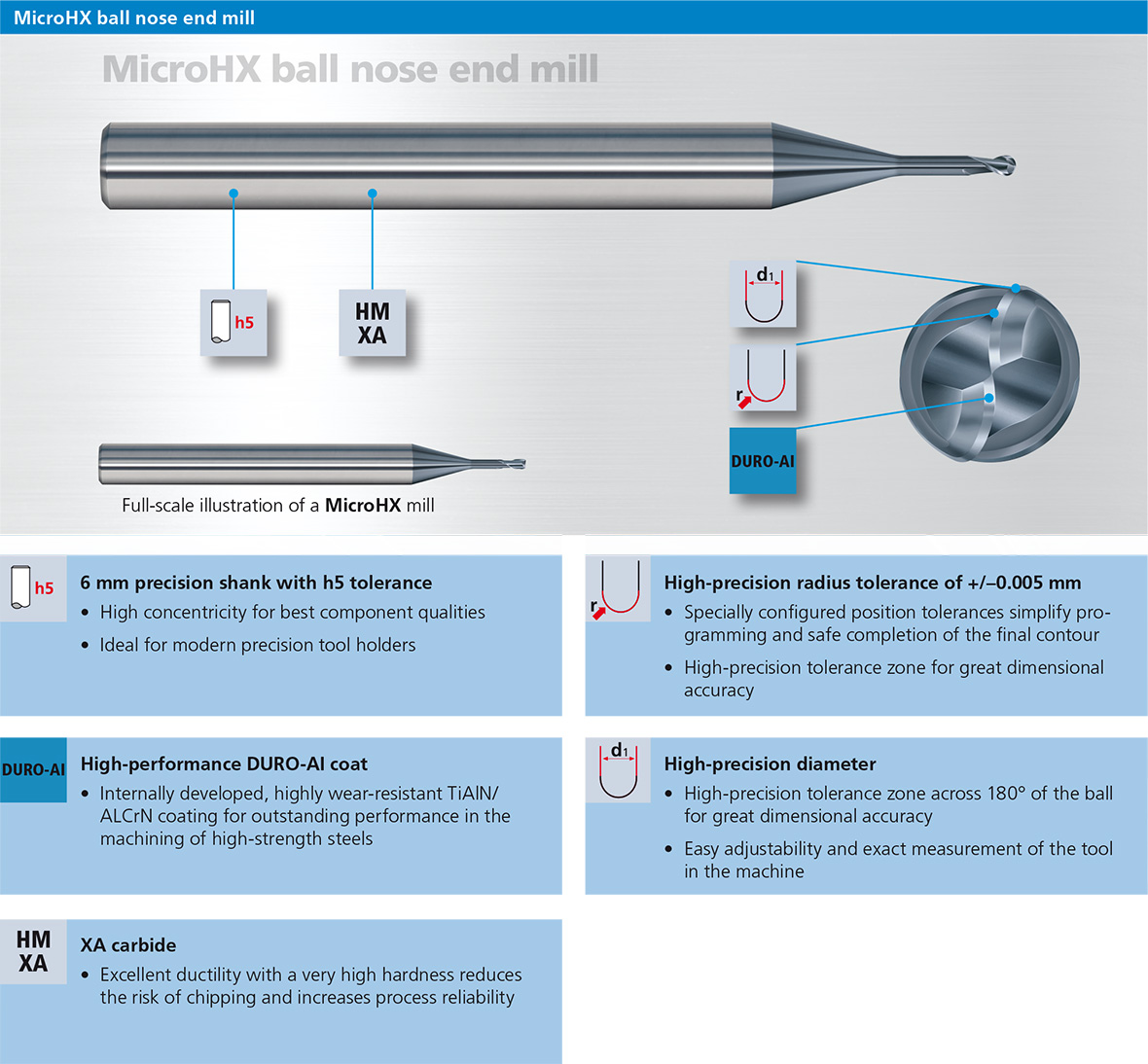

The successful and comprehensive MicroX range from FRAISA offers the right solution for every challenge in mold making. For particularly hard materials such as steel, the solution is: FRAISA MicroHX.

With the MicroHX ball nose end mills from FRAISA, very hard materials with a hardness of HRC > 60 can now also be machined extremely economically, efficiently, and precisely. The new MicroHX tools have superior service lives, are extremely wear-resistant, and can be used for a very long time.

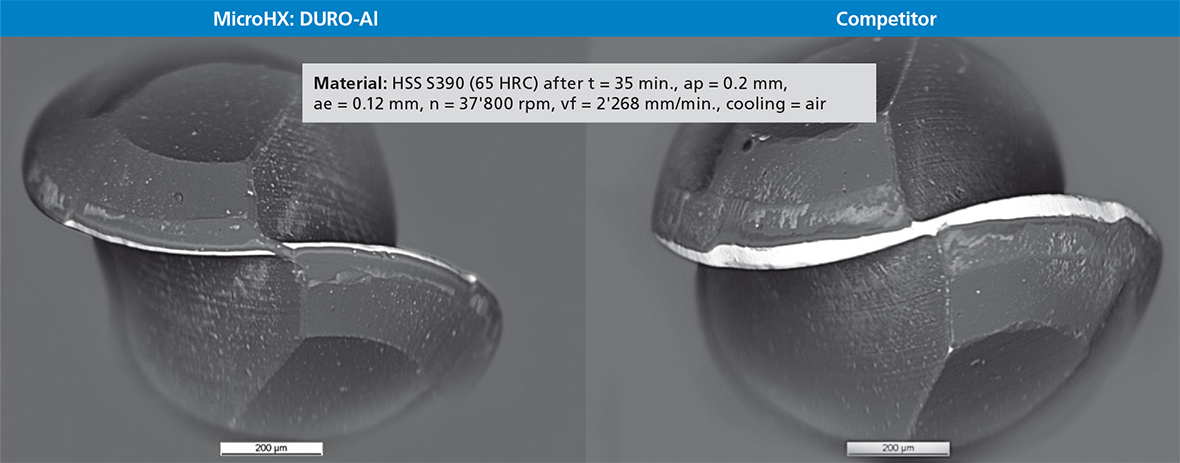

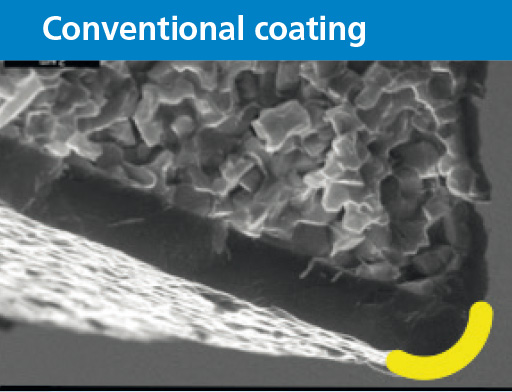

This is thanks to a completely new tool technology that revolutionizes machining and leads to impressive performance across-the-board: with their very strong and sharp cutting edge and a higher thermal load capacity, the cutters of the MicroHX series can be used up to four times longer than conventionally coated tools.

A sharp cutting edge, a thick coating, and optimum thermal management result in tool lifetimes that are 3 to 4 times longer than previous known values.

MicroHX from FRAISA is a highly innovative tool solution for the efficient production of complex, super-hard components

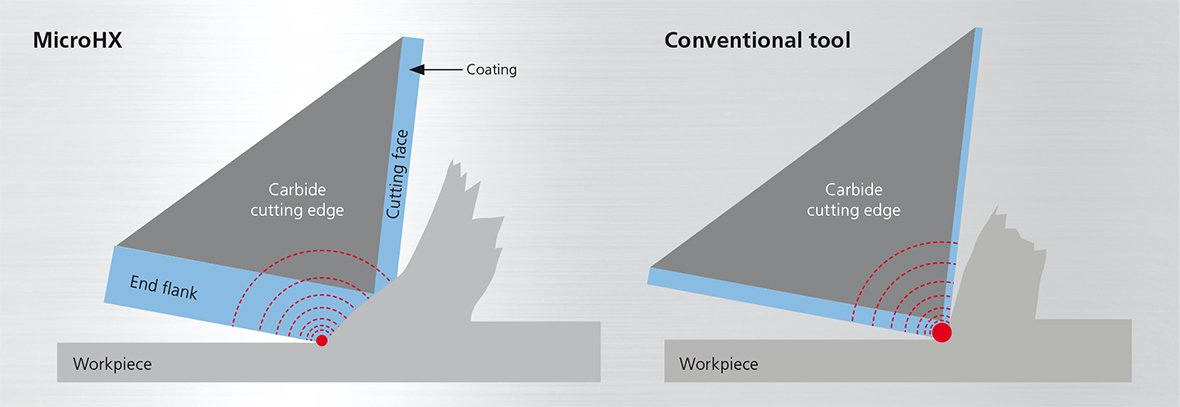

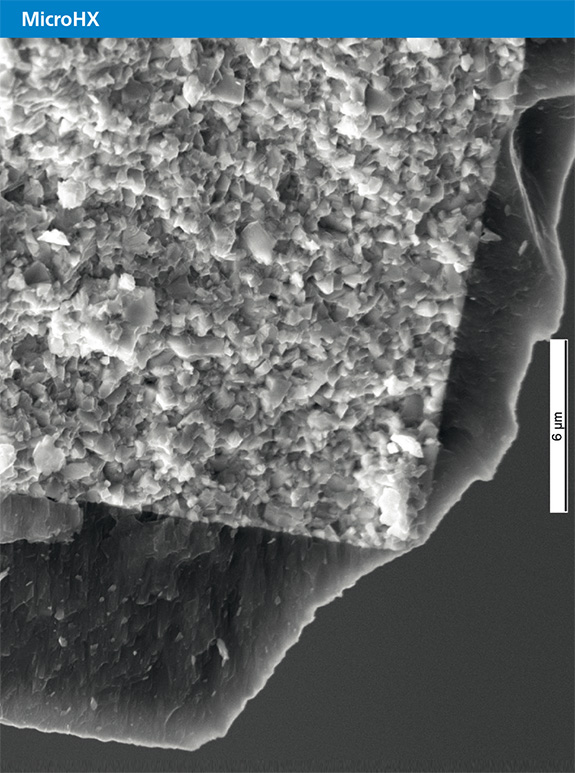

A special feature of MicroHX milling tools is the positioning of the meshed contact point behind the cutting edge. This completely new technology greatly reduces the strain on the cutting edge. In addition, the cutting edge is extremely sharp and strong, minimizing material deformation and thermal stress.

An innovative patent-pending mechanism makes this possible and provides controlled shearing of the outermost cutting edge radius in the area of the coating thickness. The residual stresses in the approx. 6 μm thick coating additionally support this effect.

MicroHX – maximum performance for the mold and die

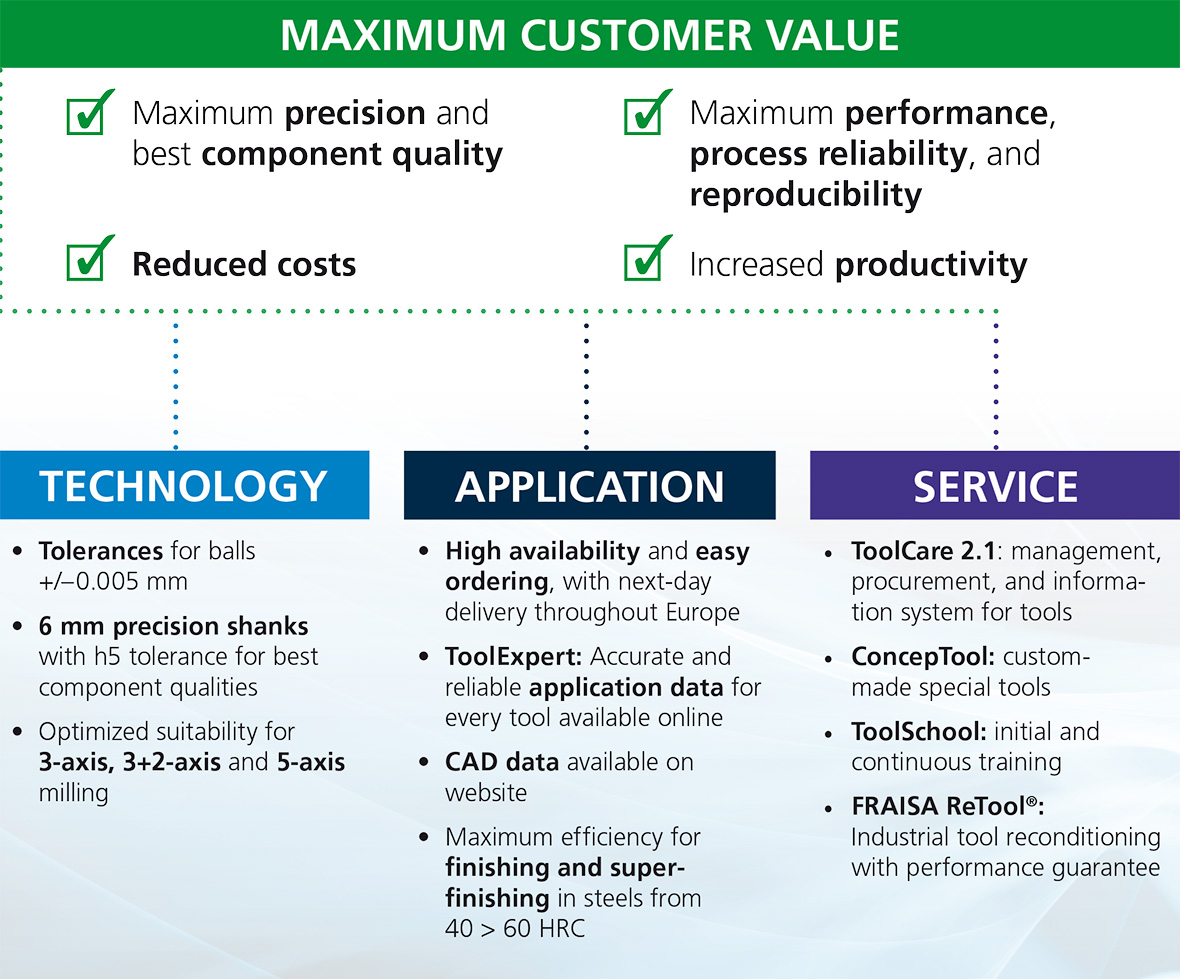

First-class milling tools with a comprehensive service package

With the MicroHX range, FRAISA not only offers the perfect tools for the precise milling of super-hard components; it also offers services that go far beyond this and ensure maximum efficiency for production processes and workflows.