Maximum performance and minimal power consumption = extreme cost reduction!

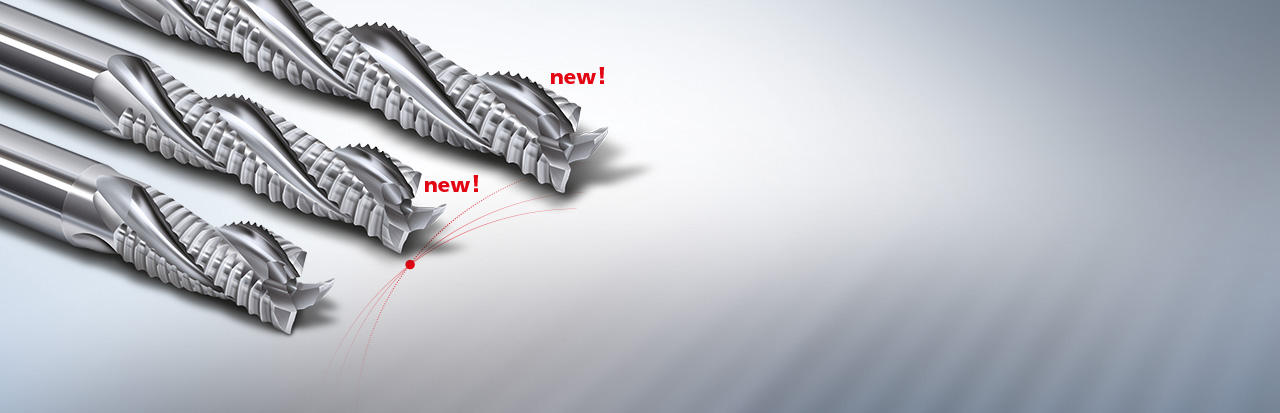

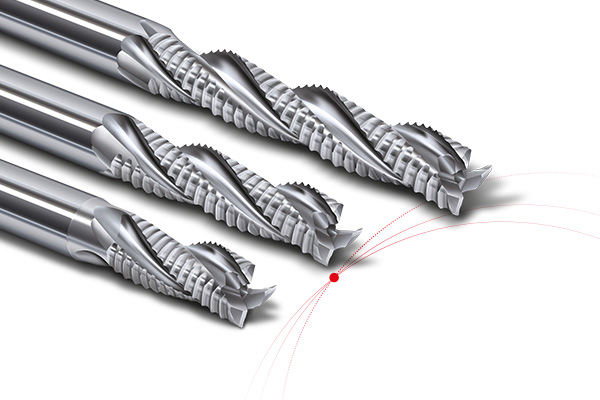

With AX-FPS, FRAISA is presenting a groundbreaking tool concept for aluminum machining.

The new AX-FPS milling cutter opens up new performance horizons in the field of aluminum machining. The as good as perfect coordination between damping and cutting ability ensures reduced power consumption and torque input by the spindle and guarantees a long service life and maximum process reliability.

In combination with the new FRAISA ToolExpert AX-FPS, the cutting parameters can be ideally matched to the spindle characteristics. This makes it possible to achieve not only productivity gains but also massive cost reductions as the tool can work at the ideal operating point of the spindle and machine environment.

AX-FPS is a contoured roughing tool with a 20° cutting angle and a helix angle of 30°. The specially designed flutes are ground to a mirror finish and precisely designed damping surfaces are attached at the curved and end cutting edges.

These geometric features form a very easy-cut tool concept and guarantee a low-vibration and safe milling process with previously unattained material removal rates per unit of time.

AX-FPS tools are equipped with the FRAISA high-performance penetration edge and central cooling channel bore. The tools are finely balanced and have a short shank with smooth transitions.

All of these technologies increase the reliability and productivity of the AX-FPS tools to an unparalleled level of performance!

The FRAISA ToolExpert AX-FPS specially developed for the AX-FPS tools enables you to determine the machine environment and to optimize the performance of the tools and the system utilization of the spindle and machine.

The benefits

- Maximum performance with minimal spindle load

Maximum productivity – low costs - High process reliability

Guaranteed chip removal thanks to mirror-finish grinding, a central cooling channel, and contoured cutting edge - Lower energy consumption per area of material milled

Extremely easy cutting

- New FRAISA ToolExpert AX-FPS

Cutting data that matches the machine spindle and machine environment - At least 2xd to 5.2xd length of cutting edge

High infeed rates, reliable chip removal, and low axial extraction force - Ideal life cycle

With FRAISA ToolCare® tool management, FRAISA ReTool® tool reconditioning, and FRAISA ReToolBlue tool recycling

Key factors: Machine spindle and machine environment

When milling aluminum, the machine tool is all too often the limiting factor. This is due to the

- reduced spindle torque at high speeds

- existing axial spindle preload and the spindle interface (example HSK-63)

- cooling lubrication and maximum coolant pressure

- tool throats and the stability of the chucking

- active spindle power

- reliable chip removal

Characteristic curves of the spindle torque and spindle power

The torque of a machine spindle decreases significantly as the speed increases. As aluminum is machined in the very highest speed range (nACT), the active torque in the operational area (MACT) is usually crucial with respect to the spindle’s performance.

One aspect that is often not taken into account but is very relevant is the bearing pretensioning of the spindle. This is why the axial tensile force must be kept as low as possible in order not to damage the spindle.

Since FRAISA has measured the power and torque requirements of the AX-FPS tools, the application data in FRAISA ToolExpert AX-FPS can be optimally positioned on the spindle characteristic to obtain maximum performance without overloading the spindle motor.

The technologies of the AX-FPS tools

A groundbreaking X-Generation

tool concept

The new AX-FPS technology is systematically designed for productivity and cost effectiveness. Very positive, easy-cut geometries paired with mirror-finish flutes ensure excellent chip formation and good chip removal, supported by a central coolant supply. Small, radially mounted surfaces on the tool circumference act as vibration dampers and result in a very smooth and reliable cut. Of course, the AX-FPS cutter also has a high-performance penetration edge that further enhances the tool’s range of applications.

Descriptions of all FRAISA technologies can be found in the main FRAISA catalog.

Use FRAISA ToolExpert AX-FPS to determine the best possible cutting data for your machine environment

The new FRAISA ToolExpert AX-FPS calculator is an innovative solution to determining cutting data that match your machine environment. High-performance roughing of wrought aluminum alloys is often not limited by the tool, but by the machine spindle being used and the actual machine environment.

Consequently, FRAISA ToolExpert AX-FPS lets you describe your machine environment clearly, so that you can determine the cutting data that is most efficient and reliable for your application. This option is unique and new and shows that FRAISA is continuing to “digitalize” its application knowhow. The outcome is a customer benefit in respect to cutting production costs and reducing machining times.

How does FRAISA ToolExpert AX-FPS work and what influencing factors are considered?

The functions built into FRAISA ToolExpert were developed from more than a thousand recorded measuring points. Highly productive and reliable system utilization comes about when the degree of capacity utilization of the milling cutter, the machine spindle, and the machine environment is as close as possible to maximum utilization.

Utilization of the milling cutter:

The optimum is the maximum possible chip removal rate of

the cutter at the speed selected. The blue bar represents the

chip removal rate with the set or recommended cutting data.

Utilization of the spindle:

The maximum is the active spindle power and the spindle

torque at the corresponding speed. The blue bar shows the

power and torque required by the tool in relation to the

active spindle power and spindle torque.

Utilization of the machine environment:

The output variable represents the cutting data recommended

by FRAISA to ensure process reliability. These were derived

from the entries made with respect to the machine environment.

The blue bar shows the difference when the operator

adjusts the cutting data.

System utilization of the milling cutter, spindle, and machine environment

The goal is to utilize the system as efficiently as possible in

order to achieve maximum productivity. FRAISA ToolExpert AX-FPS

reveals when too large a diameter has been selected, while

utilization of the spindle can be optimally adjusted by setting

reduced cutting data, the performance potential of the cutter

is far from being fully utilized. Smaller diameters are therefore

recommended for less powerful machines or spindle interfaces.

The goal is to utilize the system as efficiently as possible in order to achieve maximum productivity. FRAISA ToolExpert AX-FPS reveals when too large a diameter has been selected, while utilization of the spindle can be optimally adjusted by setting

reduced cutting data, the performance potential of the cutter is far from being fully utilized. Smaller diameters are therefore recommended for less powerful machines or spindle interfaces.

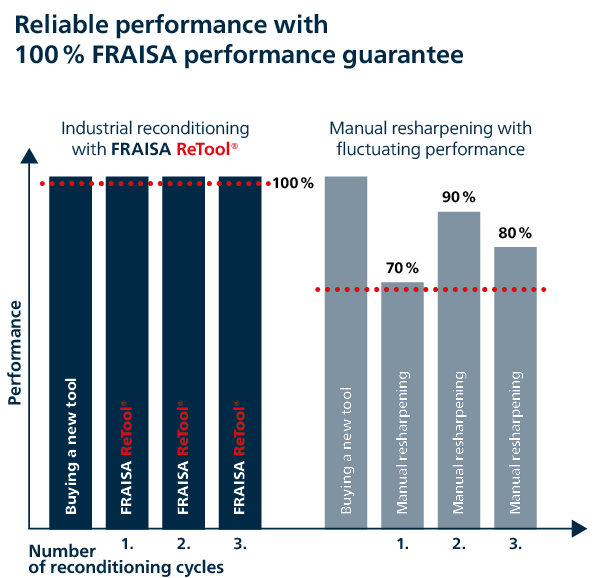

FRAISA performance guarantee through industrial reconditioning

FRAISA ReTool® guarantees 100 % of the machining performance and service life of a new tool. Industrial reconditioning is already being considered during tool development. Our automated production processes ensure maximum performance stability.

Cost savings thanks to FRAISA performance guarantee

Thanks to the FRAISA performance guarantee, you benefit from the reliable 100 % performance of the reconditioned tools. Your machines can produce at an output of 100 % – with new tools as well as after the first, second or third reconditioning.