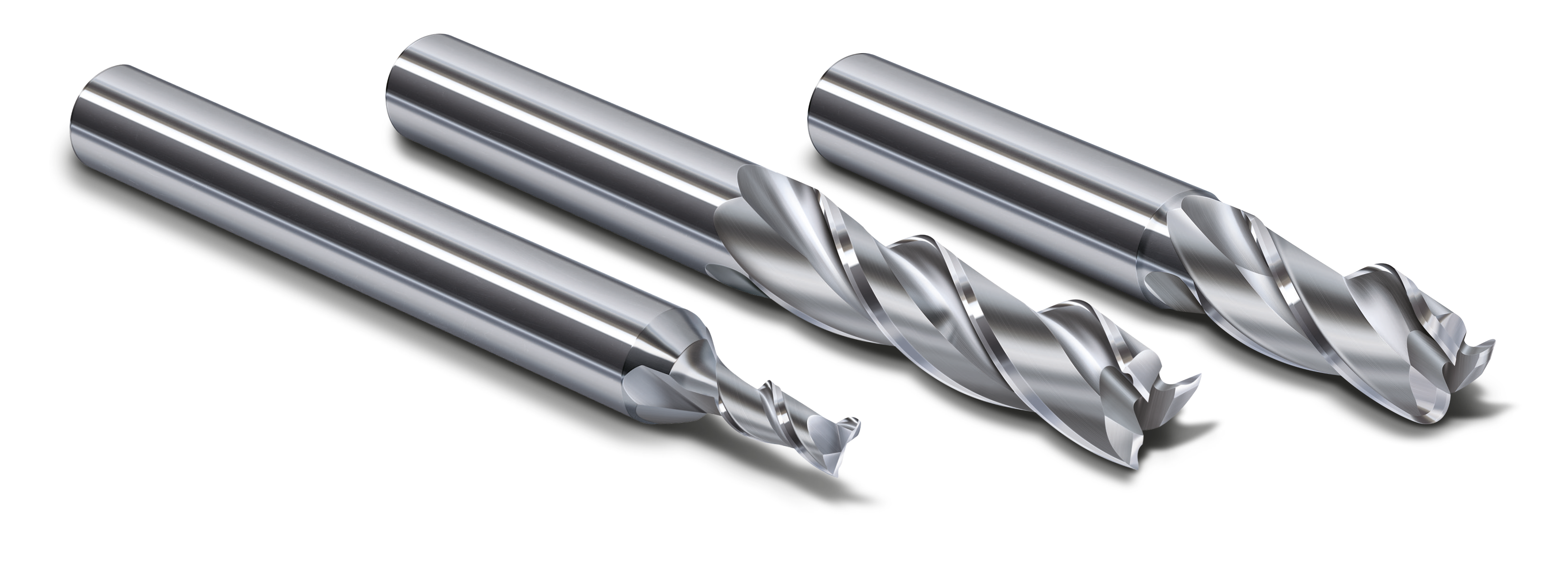

E-Cut Alu -

the perfect

tool family

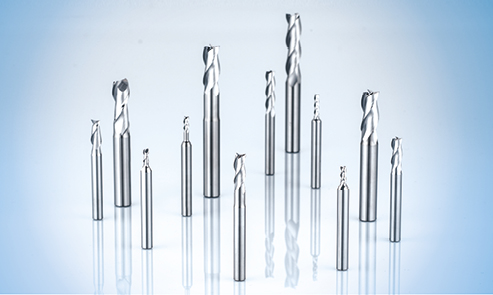

272 new tools

(dia. 1 to 20 mm)

Also for

3D machining

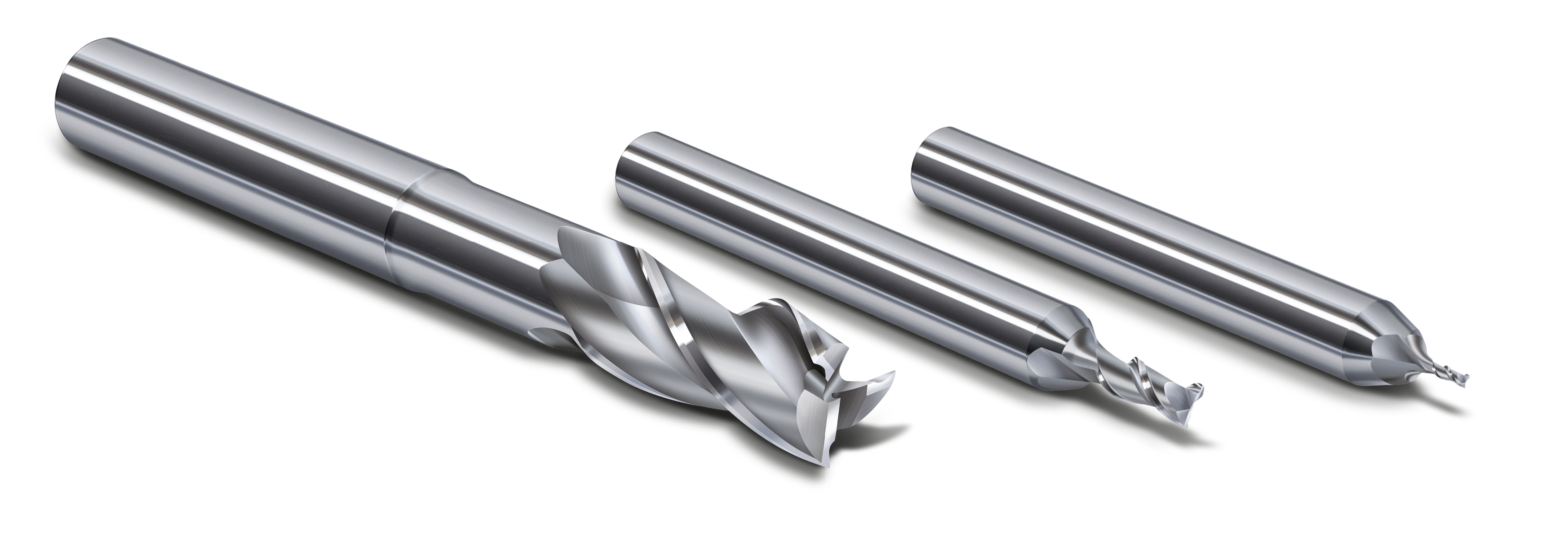

Constant l/d ratio

Verified

application data

20% less spindle

power consumption

Sustainable thanks to FRAISA ReTool®

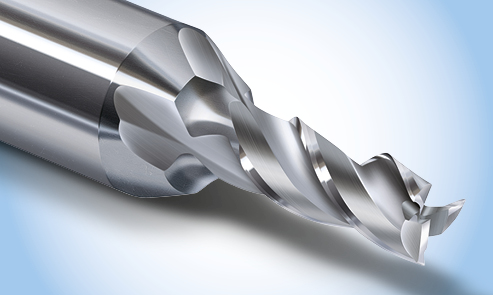

- Extremely robust thanks to optimized neck transition

- Mirror-finish cutting face

- Extremely consistent quality

- Smooth-edged, cylindrical and with corner radius

- Standard, medium-length and long versions

Simplification and improved process reliability in production

FRAISA presents the E-Cut Alu family for machining aluminum: The totally new, smooth-edged, high-performance milling system includes over 272 articles with, for the first time, constant l/d ratios throughout. A new standard that makes these tools much easier to use and gives them improved performance, especially the standard and medium-long versions.

The milling cutters of the E-Cut Alu family have a very easy-cutting geometry that makes them particularly versatile. Mirror-finish cutting faces ensure rapid and low-friction chip removal. Adhesion is virtually impossible on these faces – a key reason why the E-Cut Alu tools can also be used in autonomous production with maximum process reliability. The high-precision, ground cutting edge is created by a very fine-grained and high-hard carbide substrate.

Among the impressive advantages offered by E-Cut Alu milling cutters are a long tool life, excellently finished faces and low energy consumption. Optimum l/d ratios and load-oriented neck transitions result in a unique tool composition. Perfectly coordinated cutting parameters determined in countless machining tests can be called up for these new tools in FRAISA ToolExpert®.

This in combination with our industrial tool reconditioning service FRAISA ReTool® enables us to guarantee you maximum economic and ecological benefit. What’s more, our E-Cut Alu tools are genuinely easy to use and set new benchmarks in aluminum machining.