FRAISA ReTool®

CO2MPETITIVE —

Industrial tool

reconditioning service with

performance guarantee

FRAISA performance

guarantee

Resource

conservation

Money-back

guarantee

Cost savings

Convenient processes

Transparent FRAISA

ReTool® prices

FRAISA ReTool®

100 % of the machining performance and service life of a new tool

Maximum substance preservation through adaptation of the reconditioning process to the tool condition

Personal advice from application engineers to optimize the engagement time

Wide service portfolio for many tools – available from diameters starting at 2 mm

We will gladly send you a FRAISA ReTool box free of charge for shipping your used tools. Just leave your contact details and we will take care of the rest:

Order FRAISA ReTool®-BoxFRAISA ReTool® packaging cores -

100 % recycled

With the sustainable FRAISA ReTool® service, FRAISA is taking responsibility for the careful use of resources.

We are now taking the next step towards a sustainable future: FRAISA ReTool® packaging cores are gradually being converted to a material that is 100% recycled.

With this changeover, we are helping to further improve our carbon footprint and also support our customers in meeting their sustainability targets.

FRAISA ReTool® sets new standards in the circular economy

When our standards become the norm, our guiding principle “passion for precision” is confirmed once again:

We are proud that our industrial tool reconditioning FRAISA ReTool® is one of three practical examples in the new ISO standard ISO 59020 on the circular economy.

With our environmentally conscious service, we and our customers are helping to shape the circular economy of tomorrow - for a sustainable future.

ISO standard ISO 59020

Circular economy – Measuring and assessing circularity performance

Circular economy assessment guide:

Guidance on measuring and assessing the circular economy of an economic system using current data

Use of indicators:

Combination of mandatory and optional indicators for a comprehensive analysis of the circular economy

Versatile applicability:

Can be used at different levels of an economic system - regional, cross-company, organizational or product-related

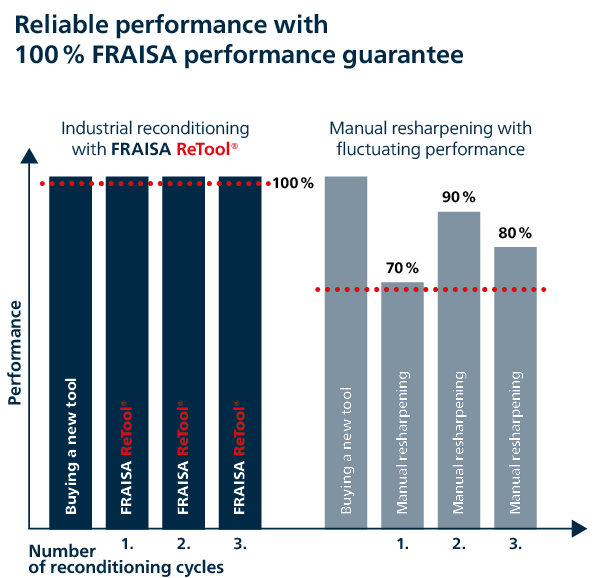

FRAISA performance guarantee through industrial reconditioning

FRAISA ReTool® guarantees 100 % of the machining performance and service life of a new tool. Industrial reconditioning is already being considered during tool development. Our automated production processes ensure maximum performance stability.

Cost savings thanks to FRAISA performance guarantee

Thanks to the FRAISA performance guarantee, you benefit from the reliable 100 % performance of the reconditioned tools. Your machines can produce at an output of 100 % – with new tools as well as after the first, second or third reconditioning.

Environmental effect and resource conservation

For tool reconditioning, fewer resources are used than for the manufacture of a new tool. The carbon footprint of FRAISA shows a reduction in CO2 emissions of 50-80 % for reconditioned tools.

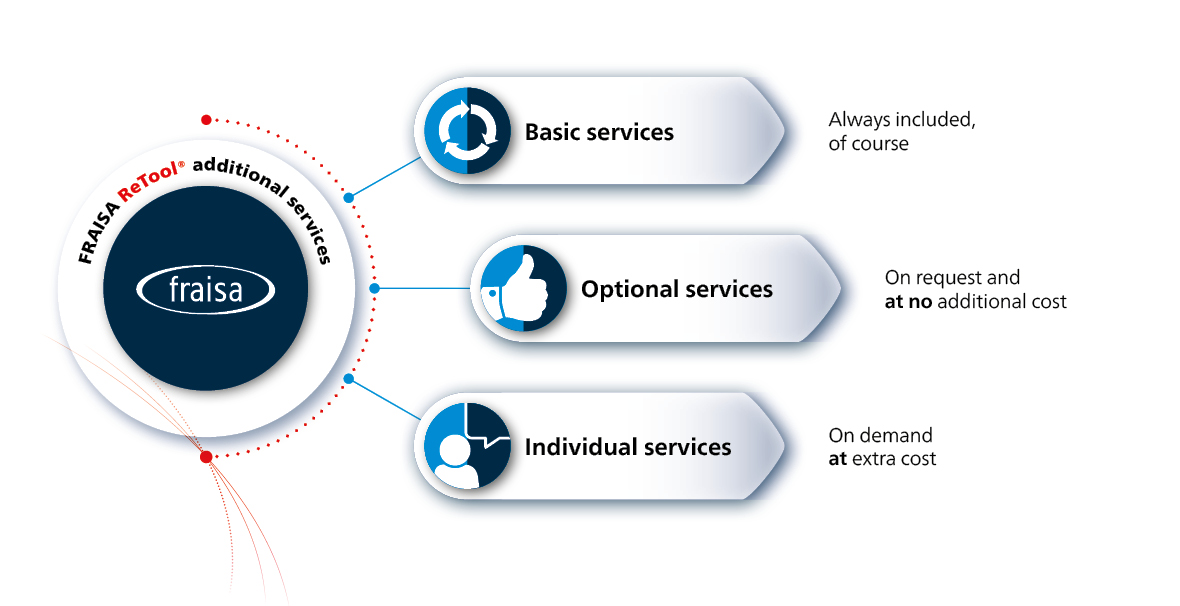

Wide service portfolio

From cylindrical universal tools to sophisticated finishing cutters and high-precision ball nose milling cutters – FRAISA ReTool® is available from diameters starting at 2 mm.

Cost savings with transparent prices

The tool reconditioning with FRAISA ReTool® is less expensive than buying a new tool – up to over 70 %. Each reconditioning has a transparent total price regardless of the tool condition. All prices can be found in the FRAISA webshop.

Advice from application engineers

The correct engagement time is decisive for the optimal use of FRAISA tools over the entire life cycle. We are happy to advise you on this in-person or through your preferred method of communication.

Cost savings through substance preservation

We adapt the reconditioning to the respective tool condition. The grinding programs are customized in order to preserve the substance of your tool as far as possible.

Money-back guarantee

Your satisfaction is guaranteed. Should we ever fail to meet your expectations, we will refund the cost or provide you with a replacement tool.

Convenient processes

We provide you with environmentally friendly recyclable packaging and organize logistics and transport. We do not require purchase orders, delivery notes and order papers.