FRAISA E-Cut finishing cutter – highest precision and process reliability

Perfect surface qualities thanks to optimized cutting edges

Maximum dimensional accuracy – ideal for precision components

Maximum stability and process reliability – even with small diameters

Minimal burr formation – for clean machining results

Perfect application data in the FRAISA ToolExpert®

Sustainable service offers with FRAISA ReTool®Services

Our E-Cut finishing cutters in use

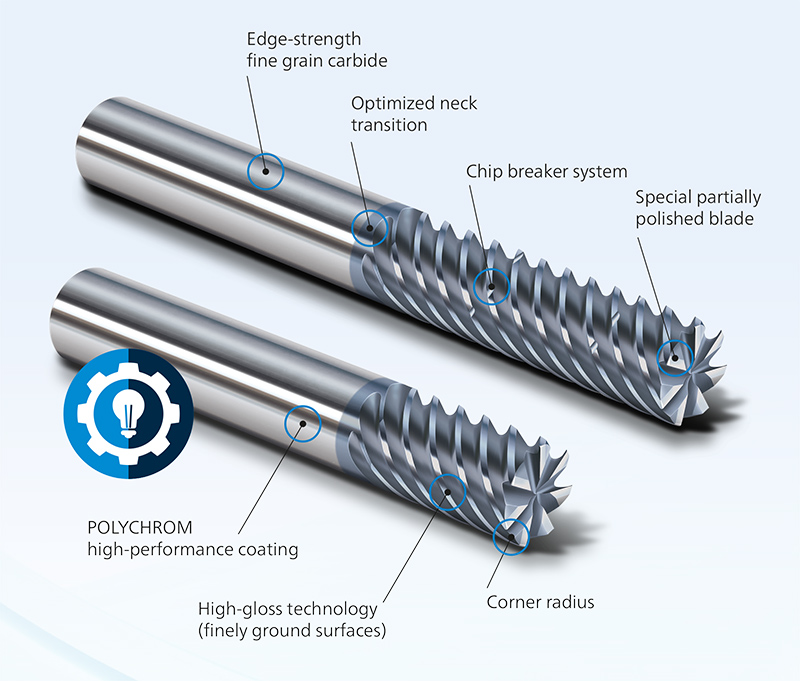

The targeted expansion of the FRAISA E-Cut range clearly focuses on high-precision finishing. The new finishing cutters impress with their outstanding quality in terms of dimensional accuracy and surface finish — both for the smallest components and in autonomous production.

- Maximum stability during fine machining thanks to optimized tool geometry

- Perfect chip formation and clean chip management thanks to the chip breaker system

- High process reliability and repeatability – ideal for autonomous machining

- Significantly longer service life thanks to finely ground flanks and stable cutting edges

- Versatile range for maximum flexibility: Ø 1–20 mm, number of teeth z4–z8

- Excellent results when machining steel, stainless steel, and harder materials

- Consistent cutting edge length/diameter ratios

Perfect finishing – systematically and reliably

The demands on finishing operations are steadily increasing: tighter tolerances, finer contours, and higher demands on surface quality require precision and process reliability at the highest level. Modern manufacturing also calls for stable, repeatable processes – preferably automated and requiring minimal manual intervention.

Product range overview:

- Diameter range: Ø 1–20 mm

- Five designs:

- short (1.5xd)

- normal with short neck (2.2xd and 3.0xd)

- medium-length (up to 3.7xd)

- 5.2xd version with chip breakers up to z8

- 6.3xd version with chip breakers up to z8

- Number of teeth: z4–z8

- Designed for high-quality fine machining

The solution for every finishing challenge: FRAISA E-Cut

From short, particularly stable end mills from Ø 1 mm to medium-length variants for complex geometries, FRAISA E-Cut’s comprehensive range of finishing cutters offers the right tool for every application. With finely ground flanks, optimized chip breaker systems, and robust transitions, these tools achieve outstanding results even with small diameters or hard-tomachine materials, while ensuring high dimensional accuracy and minimal burrs.

Process-reliable cutting data – fast, secure, and reliable

With FRAISA ToolExpert®, you get verified, proven cutting data instantly, maximizing your efficiency. This enables reliable process planning, reduces potential errors, and ensures automated machining runs smoothly and consistently.

FRAISA specialists also offer personalized application consulting to help select the right tools, define optimal strategies, and optimize your processes.

Efficient and economical finishing for perfect results

With FRAISA E-Cut finishing, you can rely on optimal results, including consistently high quality from the very first component and stable processes in series production.

Innovative technologies for maximum precision and process reliability

Thanks to the finely ground rake faces and the advanced chip breaker system, when using the new E-Cut finishing cutters, you benefit from smooth machining, minimal burr formation, and a significantly longer service life. Optimized transitions for tools < 6 mm also guarantee maximum stability—ideal for fine contours and delicate components.

The expanded range offers you an even wider selection of highly specialized tool designs. This means you will always find the right finishing cutter for your applications – take a look around our web shop.

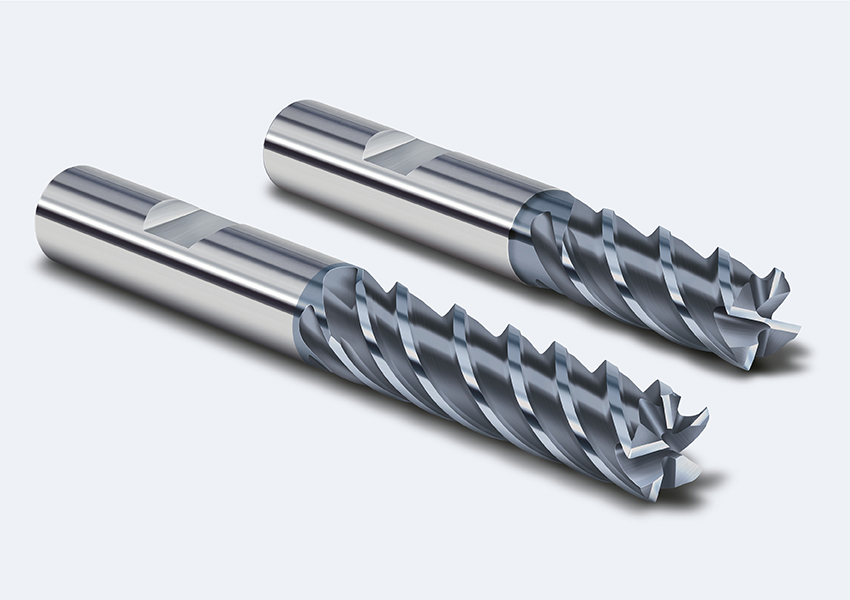

New to the range:

Normal design with short neck (2.2xd and 3.0xd) – for precise standard finishing operations

FRAISA ToolExpert®

Medium-length design (up to 3.7xd) – for greater flexibility with complex geometries

FRAISA ToolExpert®Existing product range:

Standard version up to z8 – for perfect surfaces in all steels up to 54 HRC, stainless steel, titanium, and cast iron

FRAISA ToolExpert®

Medium length design, some with chip breakers up to z8 - for perfect surfaces in all steels up to 54 HRC, stainless steel, titanium, and cast iron

FRAISA ToolExpert®

5.2xd version with chip breakers up to z8 – for perfect surfaces in all steels up to 54 HRC, stainless steel, titanium, and cast iron

FRAISA ToolExpert®

6.3xd version with chip breakers up to z8 – for perfect surfaces in all steels up to 54 HRC, stainless steel, titanium, and cast iron

FRAISA ToolExpert®The new efficient E-Cut milling cutters are the ideal choice for demanding finishing operations – the versatile range offers the right tool for every machining task. In addition, FRAISA ToolExpert® provides you with verified and precise cutting data for maximum process reliability with just a few clicks. Using our sustainable FRAISA ReTool®Services for industrial tool reconditioning also helps reduce environmental impact and lowers your process costs.

FRAISA E-Cut – the compact range

Cylindrical, high-performance E-Cut milling cutters – for HPC and HDC processing