SX – High Dynamic

Cutting HDC

High productivity

Longer tool life

Good chip formation

and removal

Sustainable thanks

to FRAISA ReTool®

Repeat accuracy and

reliability

Verified application

data

The new SX high-performance milling cutter from FRAISA has been developed specifically for machining stainless and acid-resistant steels. A high degree of universality, excellent cutting performance and a long tool life are its trademarks.

During countless cutting trials, the cutting-edge geometry has been optimized in such a way that maximum stability and very low-friction chip discharge have been achieved at the same time. The result is silky smooth running of the cutter with low cutting forces.

Very tough but also abrasive rustproof and acid-resistant materials pose a challenging complex of loads for tools. Ultrafine- grain carbides have a high hardness and considerable edge strength.

Ultrafine-grain carbides form the basis of our SX high-performance milling cutters. To protect the carbide from high temperatures and abrasive wear, an extremely smooth DURO-Si hard coating was chosen. As a result, the structure of the cutters is made up of perfectly coordinated components.

In addition to FRAISA’s innovative tool and production technology, the expertise of the cutting data was matched to the materials of the “INOX” group and integrated in the new ToolExpert cutting data calculator. It guarantees simple, reliable, and fast implementation in production. This makes milling difficult stainless and heat-resistant steels easy.

The wide range of applications SX high-performance milling cutters are capable of is another big benefit of this new technology. In addition to the main purpose for which they were designed, namely HPC processes, these cutters are also ideal for HDC machining. After use, the tools can be restored to their original condition by the FRAISA ReTool® reconditioning service.

The advantages

- Excellent cost-performance ratio:

- High performance, long tool life, repeat accuracy and reliability

- ToolCare® tool management, ToolLab application training and FRAISA ReTool® tool reconditioning

- Application know-how for stainless, acid- and temperature-resistant steels

- Comprehensive range with catalog cutting data

- Diameters between 3 mm and 20 mm

- Two different lengths: standard and medium-long

- Specially developed catalog cutting data for HPC machining

- Tools with a corner radius available on request (custom-made)

- Wide range of applications

- For replacing existing tools and as a solution for new applications

- HPC machining with 65% RDOC and 1.5xd ADOC, ToolExpert with HDC machining

- Maximum performance thanks to the perfect combination of tool type and cutting data

- Soft-cutting tools for dependable use in demanding applications

- Perfection – FRAISA ToolExpert®

- Completely revised cutting performance data and revised material table

- Quick, simple, and reliable cutting-data search function by entering the material number

- Automatic data transfer to CAM

The technologies of the SX high-performance tools

The new SX technology was developed in FRAISA’s Production department and Test Center, while the FRAISA ToolSchool was responsible for developing and validating the cutting data. All product development measures were focused on achieving high productivity, a long tool life and cost efficiency.

A strong-edged, ultrafine-grain carbide with excellent wear properties forms the basis of the SX high-performance tools. A positive, easy-cut geometry was combined with optimized flutes and an increasing tool core diameter. The result: Optimum chip formation, good chip removal, and high tool stability.

To ensure the SX tools can withstand high mechanical and thermal stresses, the exposed cutting-edge corner has been equipped with a special robust, polished tooth edge and a small corner radius.

The high-performance DURO-Si coating protects the tools against high temperature loads and ensures maximum performance and tool life by means of its high wear resistance. The SX high-performance tools are ideally suited to HPC and HDC machining and consequently cover a wide range of applications and materials.

Detailed descriptions of each technology can be found in our “High-performance Milling Tools” catalog.

FRAISA tool technology for maximum competitiveness!

FRAISA carries out extensive tests with its own high-performance milling cutters and milling tools made by competitors. We do this to keep a constant eye on the status quo in tool and application technology. These tests involve using the milling cutters in different materials with different milling strategies.

A special focus is placed on HDC milling: Due to the high mechanical and thermal loads, testing with this milling process is particularly intensive. This ensures that the tools can be used for a wide range of materials and applications – while also providing maximum performance and a long service life.

Application expertise for optimum results

Machining stainless, acid- and heat-resistant steels is a

particular challenge. Using the right high-performance tool and the appropriate cutting data for the job is crucial. But it’s also essential to monitor other factors and make optimizations if necessary.

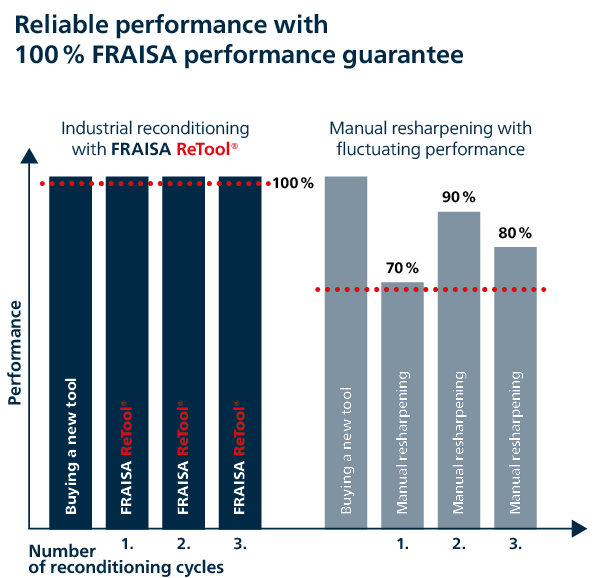

FRAISA performance guarantee through industrial reconditioning

FRAISA ReTool® guarantees 100 % of the machining performance and service life of a new tool. Industrial reconditioning is already being considered during tool development. Our automated production processes ensure maximum performance stability.

Cost savings thanks to FRAISA performance guarantee

Thanks to the FRAISA performance guarantee, you benefit from the reliable 100 % performance of the reconditioned tools. Your machines can produce at an output of 100 % – with new tools as well as after the first, second or third reconditioning.

Downloads