SX – High Dynamic

Cutting HDC

20% higher

productivity

30 % longer

tool life

FRAISA product

quality

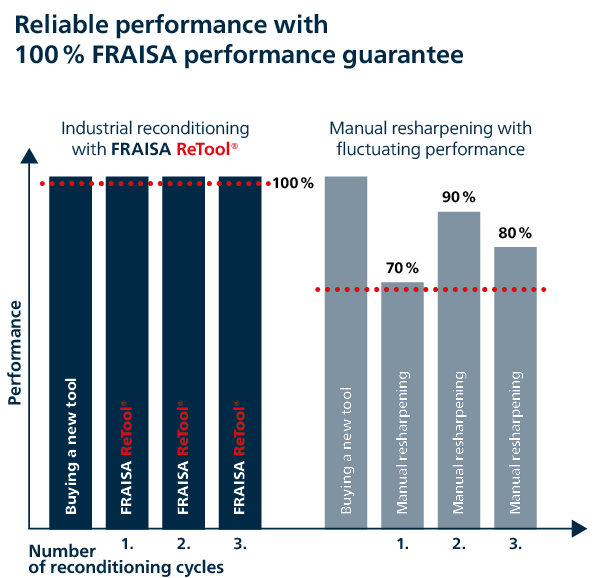

Sustainable thanks

to FRAISA ReTool®

Process stability

that inspires

Verified application

data

- Smooth running characteristics

- Small chips

- Robust core

- Extremely wear-resistant

- Lots of cutting edges

- Internal cooling

SX high-performance milling cutters for HDC – perfectly coordinated and extremely potent

With its multi-tooth SX high-performance milling cutters, FRAISA has developed a completely new milling series designed specifically for machining all stainless steels and difficult-to-machine materials. The tool technologies and application data have been specifically configured for penetration and high-performance High Dynamic Cutting (HDC) machining.

The tough, abrasive materials result in the cutting edges being subject to extremely high thermal and mechanical loads. The number of cutting edges has been increased so that the load is distributed over more teeth and the service life of the tools can be significantly extended. As a result, you benefit from high productivity and a long tool life by choosing to use the new SX tools.

With the new DURO-XI coating, stainless steels and nickel-based alloys, which effectuate the highest thermal as well as abrasive loads on the cutting edges, are able to be machined. Thanks to their optimized flute geometry and extremely light and low-vibration cut, SX milling cutters henable you to achieve the highest stock removal rates. Also new: the high-performance penetration edge for multiple flutes enables rapid penetration – actively supported by the central cooling channel bore at the center of the end face. The new chip breaker concept additionally ensures that no machining zones or machine spaces are blocked by long chips.

Parallel to developing the tools, we also compiled the necessary application knowledge. FRAISA ToolExpert® 2.0 provides you with perfectly coordinated cutting data to ensure optimum tool use. Prerequisite for utilizing this outstanding tool technology is a CAM system that facilitates HDC programming.

Supplementary service offers for FRAISA SX – High Dynamic Cutting HDC

Downloads

Do you have questions about our products?

We are happy to help!

FRAISA SA

Gurzelenstrasse 7

CH-4512 Bellach

Schweiz

Tel.: +41 (0)32 617 42 42

E-Mail: mail.ch@fraisa.com

FRAISA GmbH

Hanns-Martin-Schleyer-Str. 15b

D-47877 Willich

Deutschland

Tel.: +49 (0)2154 489 84-0

E-Mail: info.de@fraisa.com

FRAISA Sarl.

7, Rue de Lombardie

ZA Les Pivolles

F-69150 Décines

Tel.: +33 (0)4 72 14 57 00

E-Mail: fraisa@fraisa.fr

FRAISA Italia s.r.l.

Via Grosio 10/8

I-20151 Milano

Italia

Tel.: +39 02 33406 086

E-Mail: info.it@fraisa.com

FRAISA Hungária Kft.

Vásárhelyi Pál utca 3

H-3950 Sárospatak

Hungária

Tel.: +36 47 312 686

E-Mail: info@fraisa.hu

FRAISA USA, Inc.

1265 Grey Fox Road, Suite 600

Arden Hills, MN 55112

USA

Tel.: +1 (651) 636-8488

E-Mail: info.us@fraisa.com

FRAISA (Shanghai) Co., Ltd

A202, Building 3, No.526,

3rd East Fute Road

Shanghai Pilot Free Trade Zone

Shanghai 200131

P.R.China

Tel.: +86 21 5820 5550

E-Mail: infochina@fraisa.com