XFeed-H – the specialist for high-feed machining

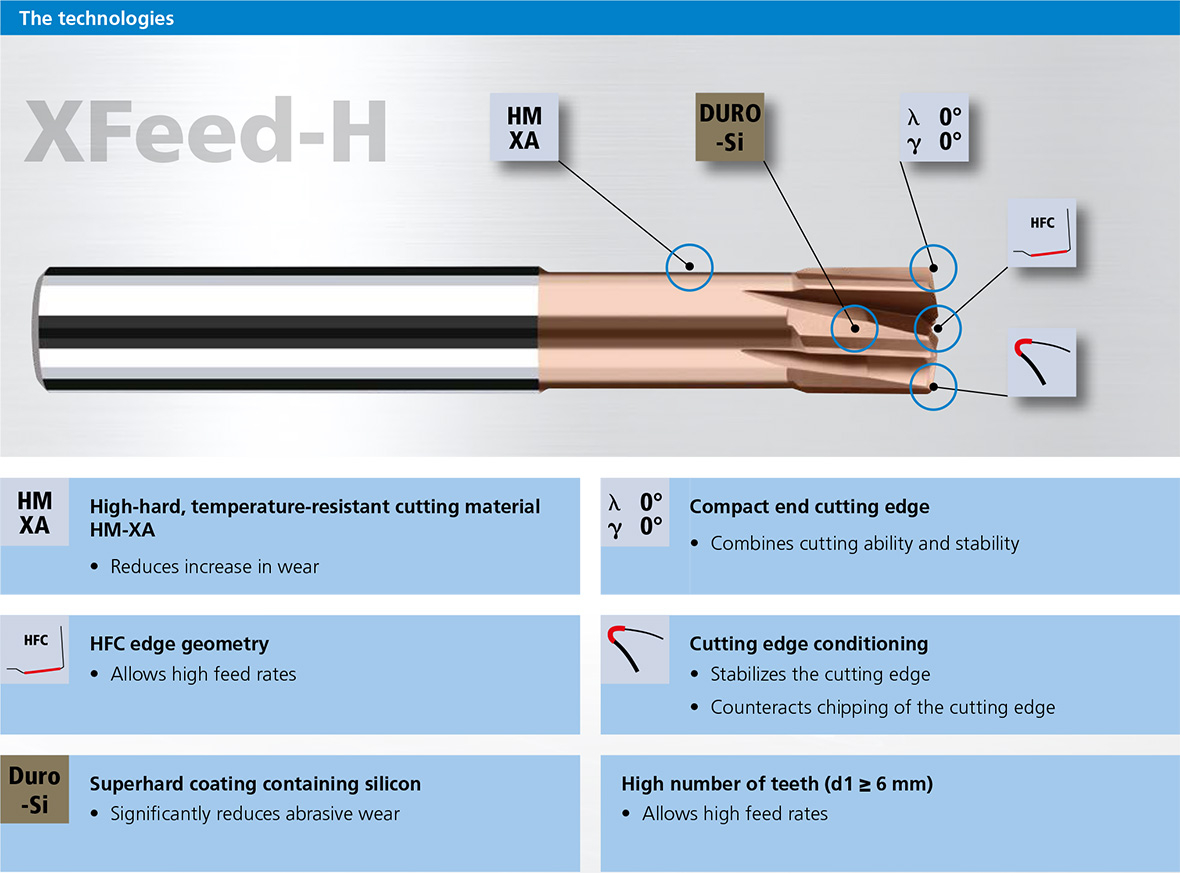

With the new XFeed-H milling cutter, FRAISA has produced the perfect tool for realizing HFC processes in hardened steels. Very high feed rates, high cutting speeds and minimal axial engagement depths characterize the strategy of High Feed Cutting (HFC). As a result, this milling concept allows the line-by-line machining of 3D contours in hardened steels – efficiently and quickly.

High chip removal rates are achieved by means of maximum feed rates, with the cutting geometry and the precisely configured machining parameters being coordinated perfectly with one another. The new HFC milling cutter has been designed especially for use in mold and tool making and for machining hardened steels.

The XFeed-H guarantees high productivity while keeping tool costs low – especially when high track speeds can be realized on highly dynamic machines. The high process stability of the XFeed-H means it is predestined for applications that run autonomously.

The design of the penetration edge of the XFeed-H is the key to its performance. A very fine-grained and high-hard carbide forms the basis of the cutting edge to enable it to safely absorb the high mechanical and thermal stresses it is subjected to. An extremely hard and temperatureresistant coating protects the cutting edge. The machining parameters, which are perfectly matched to the cutting edge, shift the main load away from the cutting edge, guaranteeing a long tool life and high process stability.

The advantages

- Shorter throughput times: From the blank to very close to the final contour (near net shape) in one process – hardened workpieces can be machined efficiently and throughput times drastically reduced

- Near-net-shape result thanks to small axial steps during roughing

- Optimum automation thanks to reliable application

- Productivity increase thanks to increased chip removal rates resulting from maximum feed rates and robust tool design

- Easy programming in the CAM system

Penetration edge facilitates excellent performance

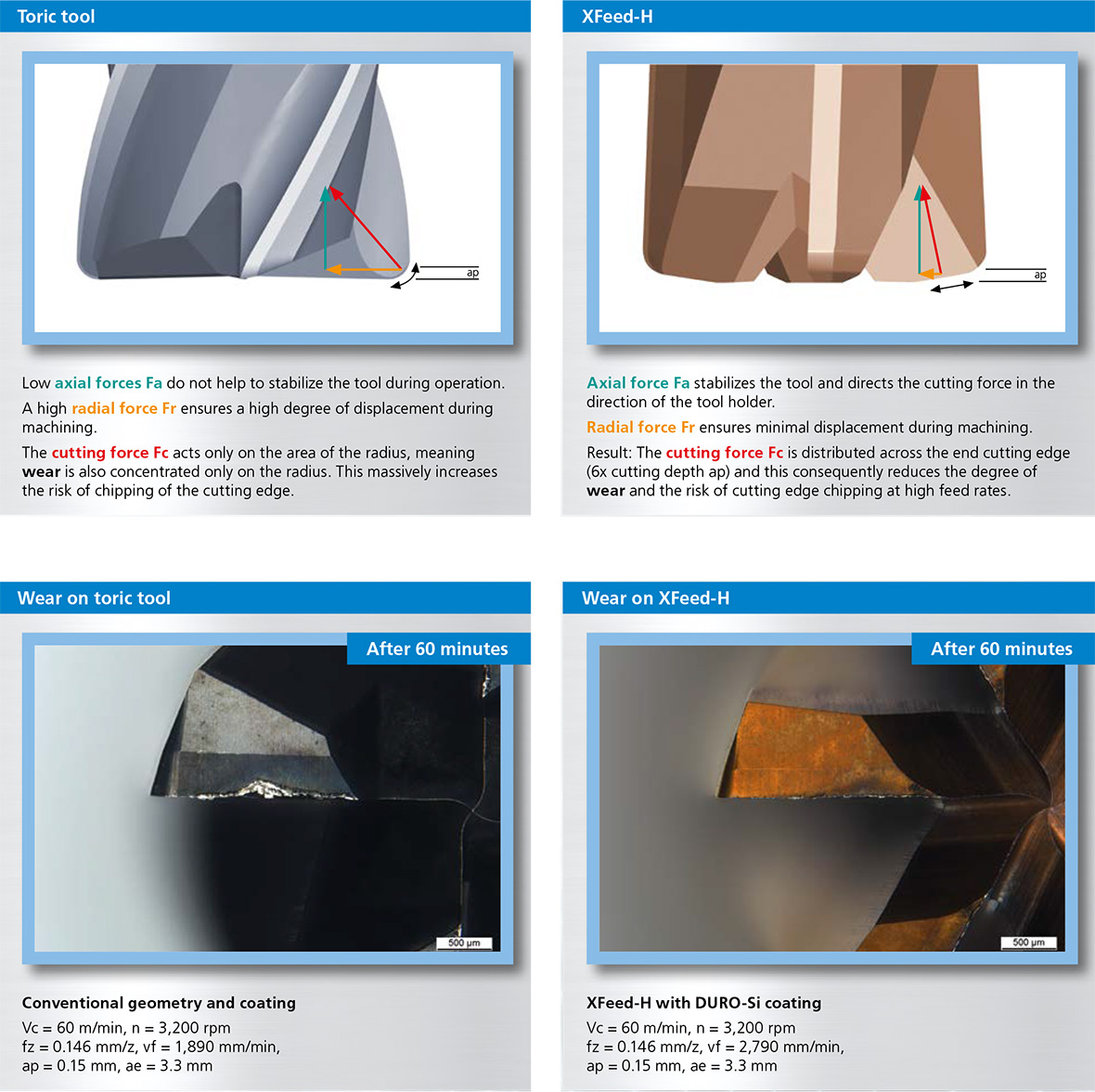

The shape of the end cutting edge of the XFeed-H greatly increases the effective length of the cutting edge. As a result, the mechanical stress and wear are optimally distributed along the end cutting edge. Feed rates and therefore also the chip removal rate can be significantly increased.

Due to the lack of a curved cutting edge, the tooth face width can be increased, giving the tool extra stability. The forces resulting from the high feed rate are consequently absorbed with ease.

XFeed-H – faster machining and high process reliability at the same time

Shorter throughput times

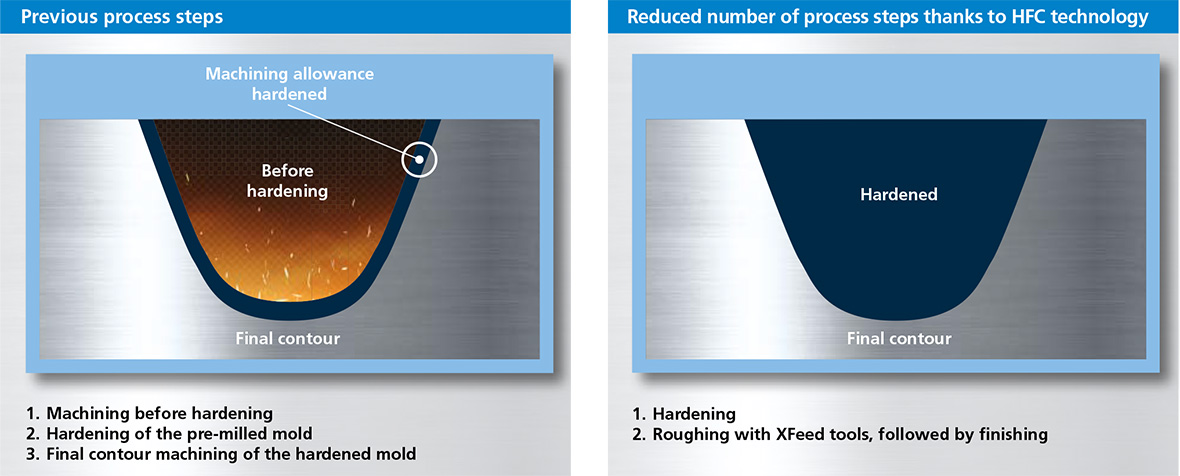

In conventional work sequences, mold blanks are machined before being hardened and finished with a machining allowance. Idle times before and after the hardening process result in high throughput times.

The big advantage of HFC milling cutters is that the entire milling process can be carried out after the mold has been hardened.

This significantly shortens the throughput time for mold production. Small, axial line steps ensure near-net-shape roughing of the hardened workpiece. This saves time and money as subsequent finishing processes can be implemented much faster.

Optimum automation

Autonomous manufacturing continues to gain ground. Process reliability is the key to success here The perfect interaction between the cutting parameters from ToolExpert 2.0 and the tool geometry forms a sound foundation for long and highly productive operating times.

Advantages when using the tools:

- Optimum operating parameters can be found quickly and reliably

- Use of perfectly coordinated, tool- and material-specific cutting data

- CAD data for selected tools is available for download

High productivity thanks to effective edge geometry

XFeed-H tool family

The new HFC milling cutters from FRAISA are available in three different lengths with throats 3xd, 4.5xd and 6xd long.

All HFC milling cutters can be reconditioned after use.

FRAISA ReTool® offers an all-round service that restores used tools to their

original performance level – using the very latest technology and in a resourcefriendly

way. Our ability to provide this performance guarantee is a priority of our

team of experts right from very early on in product development.

The outcome: mint-condition tools as productive as they were the first day they

were used.

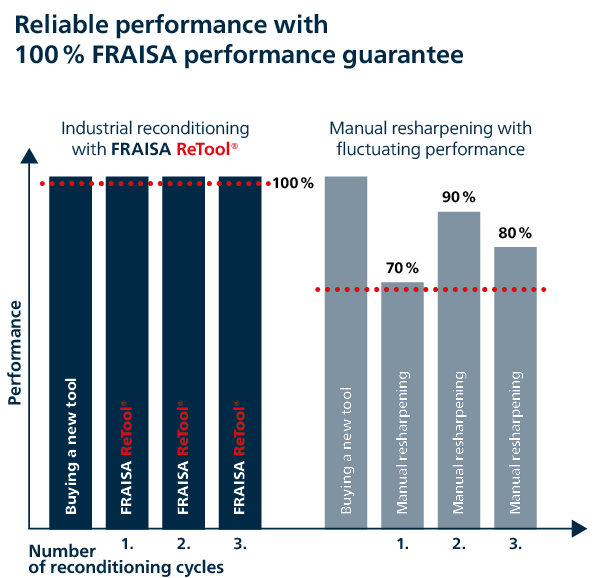

FRAISA performance guarantee through industrial reconditioning

FRAISA ReTool® guarantees 100 % of the machining performance and service life of a new tool. Industrial reconditioning is already being considered during tool development. Our automated production processes ensure maximum performance stability.

Cost savings thanks to FRAISA performance guarantee

Thanks to the FRAISA performance guarantee, you benefit from the reliable 100 % performance of the reconditioned tools. Your machines can produce at an output of 100 % – with new tools as well as after the first, second or third reconditioning.