FRAISA E-Cut – the compact range

High-performance machining made easy!

Great performance at an attractive price

Easy to handle, safe and reliable

Flexibility and speed in the production process

Ideally suited for autonomous processes

Maximum performance and process reliability thanks to precise cutting data in FRAISA ToolExpert®

Wide range of cylindrical milling cutters and finishing cutters

FRAISA E-Cut – easy to use, highly efficient, and extremely economical

The FRAISA E-Cut milling concept combines a very wide range of applications with precisely calculated and verified application data. This makes the tools extremely easy to work with. With just a few clicks, FRAISA ToolExpert® delivers perfectly coordinated cutting data. The verified application data guarantee long tool life with high stock removal rates. Simply easy to use!

The versatile tools of the FRAISA E-Cut range can be used to machine various materials without any problems. You can also rely on these robust and easy-cutting tools in autonomous production – they guarantee both smooth running and low power consumption.

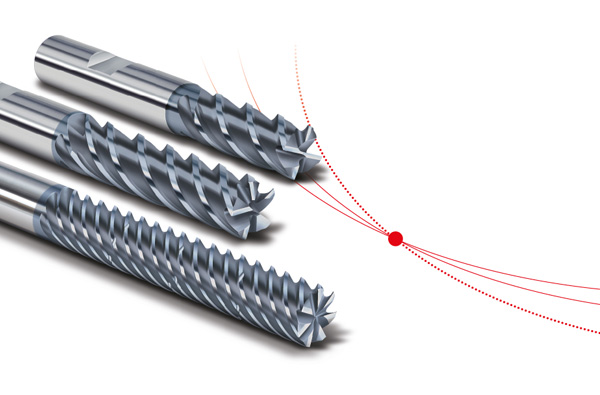

FRAISA E-Cut is available in three different lengths, with between 3 and 5 teeth, and also as a finishing tool. This provides you with a versatile range of products that can be used for a wide variety of machining operations and offers sustainability and cost-efficiency.

The tools, cutting data, and application range of FRAISA E-Cut are perfectly coordinated. Put your trust in the excellent quality of these new FRAISA tools and benefit from their ease of use, reliable performance, and cost-effective versatility. Our FRAISA application engineers are always available to assist you in selecting the right milling cutters, milling strategies, and application data.

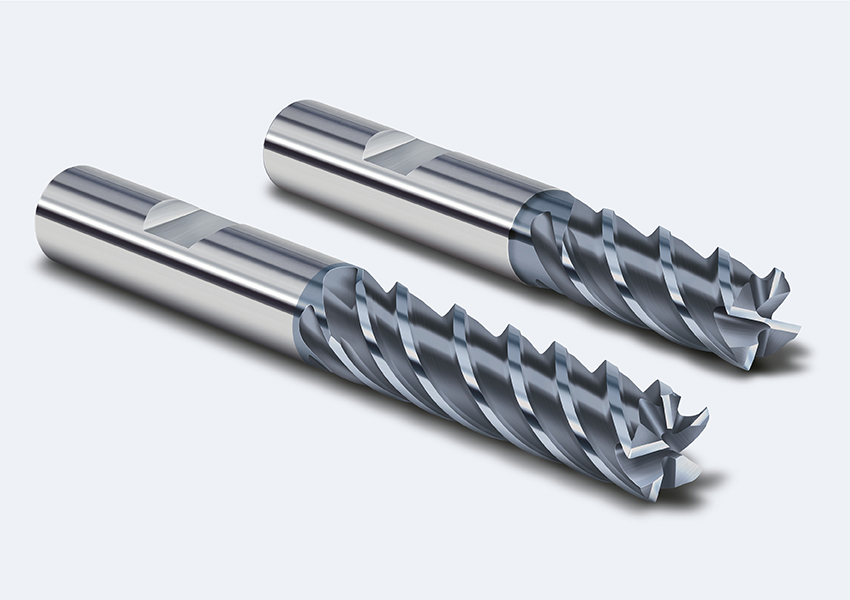

FRAISA E-Cut finishing cutters – expanded range for perfect surface finishes

Cylindrical, high-performance E-Cut milling cutters – for HPC and HDC processing